No products in the basket.

For soldering stations, HAKKO, Nitrogen compatible, Product catalogue, Shop by brand, Soldering equipment, Soldering irons

FX8802 N2 Soldering Iron and Tip

SKU: HFX8802-01

Availability:

Available for order*

N2 soldering iron designed exclusively for HAKKO FX-888D, FX-889, FR-701 and FR-702

Comes With T18-B Soldering Tip

£211.96 Excl. VAT

Available for order*

Operating a Nitrogen Soldering Iron has many benefits over traditional Soldering Irons to improve productivity and extend the process window:

- The Nitrogen has a Pre-heating effect on components resulting in faster flow of solder.

- Soldering under Nitrogen prevents oxidisation

This aids the operation of the flux in cleaning the surfaces to be joined and opens/widens the process window and aids the flow of the solder thus offering a higher process yield, e.g. Reduced solder bridging, icicling and damage caused by excessive heat application.

- Allows higher output and productivity

Traditionally Nitrogen systems have been costly to run, however with the Hakko Nitrogen Generator (FX-780) and flow Meter (FX-791) Hakko have transformed the workspace without the need for large external storage tanks or connection to external sources.

Can be used with your existing HAKKO FX-888(*Discontinued),HAKKO FX-888D, HAKKO FX-889,HAKKO FR-701 or HAKKO FR-702 soldering station.

Specifications

| Model No. | FX-8802 |

| Power consumption | 65W(26V) |

| Temperature range | 50 to 480°C |

| Tip to ground resistance | <2Ω |

| Tip to ground potential | <2mV |

| Heating element | Ceramic heater |

| Standard tip | Shape-B (No.T18-B) |

| Cord length | 1.2m |

| Total length | 190mm(with B tip) |

| Weight | 59g(with B tip and nozzle assembly A) |

* Total length and weight (w/o cord, tube)

* The setting temperature range of FX-888 is from 200 to 480°C.

* Do not set the temperature over 450°C

Combination Example

Set example:HAKKO FX-888D

- N2 soldering iron FX8802

- Soldering tip T18-B (Shape B),

- Nozzle assembly A,

- Shield plate (for Iron Stand),

- Instruction manual

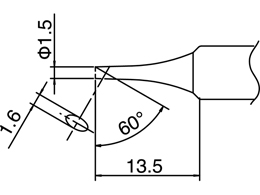

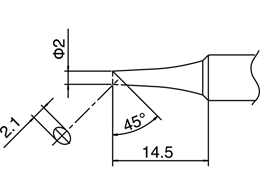

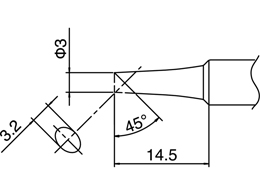

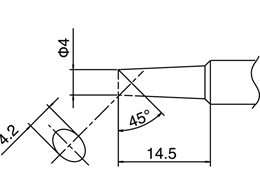

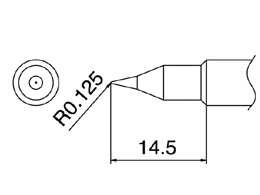

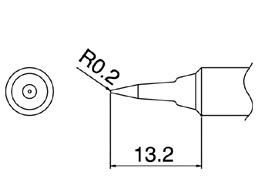

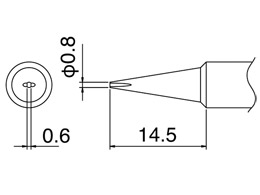

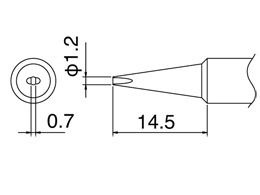

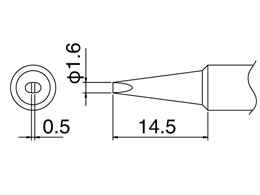

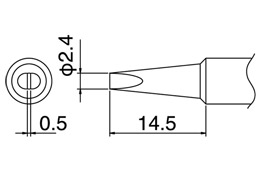

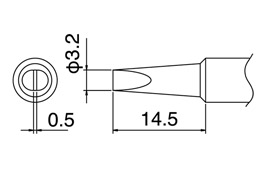

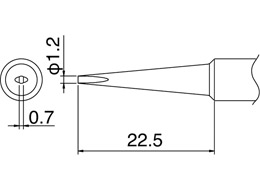

Tip Shape | Tip | Part Number |

|

B, 0.8, 1.2D, 2C | T18-B, T18-D08, T18-C2, T18-CF2 | B3662 Nozzle A | |

1.6D, 2.4D, 3C | T18-D16, T18-D24, T18-C3, T18-CF3 | B3663 Nozzle B | |

0.5C, 1C, I | T18-C05, T18-C1, T18-CF1, T18-I | B3664 Nozzle C | |

K | T18-K | B3665 Nozzle D |

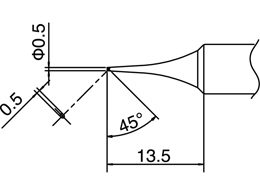

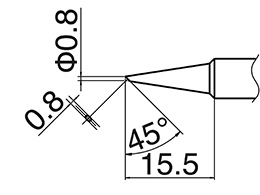

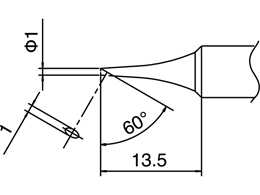

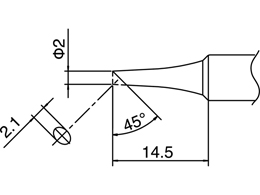

T18 Series

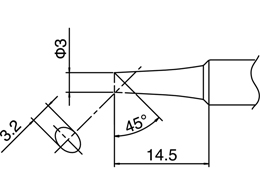

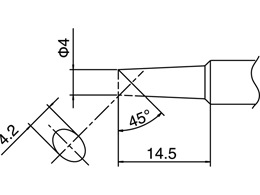

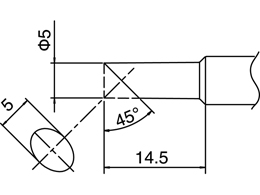

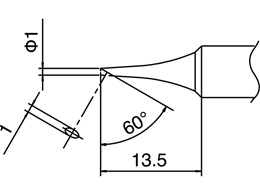

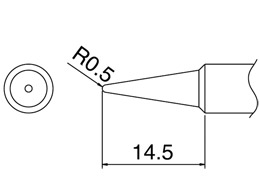

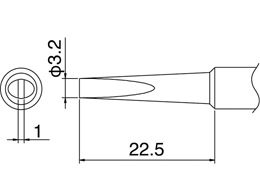

Shape BC/C

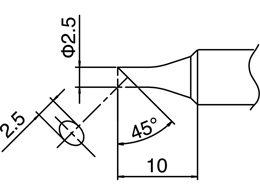

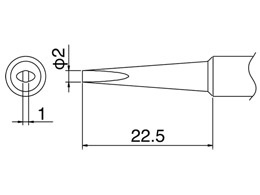

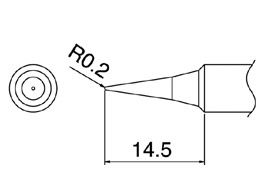

Shape B

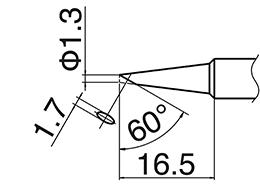

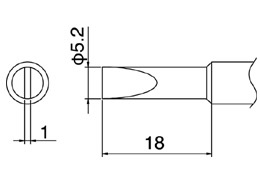

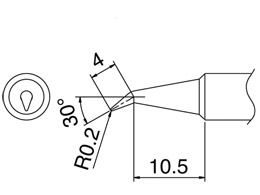

Shape D

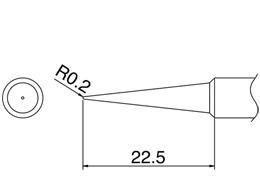

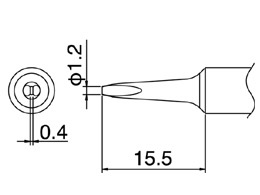

Shape I

Shape J

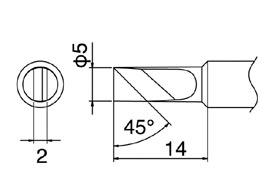

Shape K

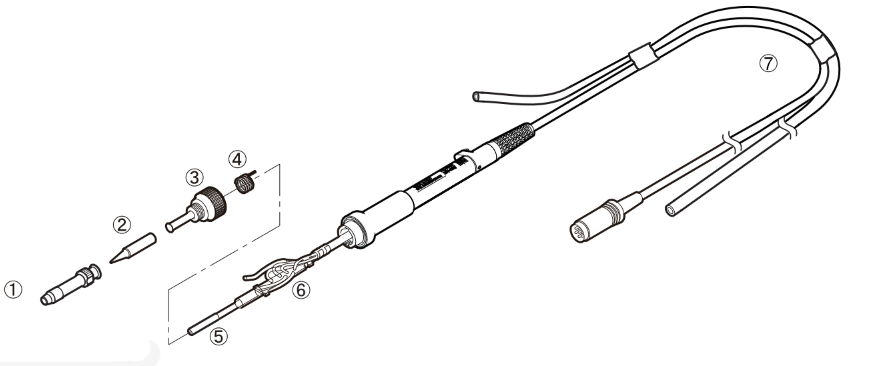

| Replacement Part | Description | |

| 1. | Nozzle Assembly | See Tips Tab |

| 2. | T18 Tip | See Tips Tab |

| 3. B2676 | Nipple | |

| 4. B2032 | Grounding Spring | Buy |

| 5. A1560 | Heating Element | Buy |

| 6. B2028 | PCB Terminal Board | Buy |

| 7. B3022 | Urethane Hose | Buy |

| - B3661 | Back Plate for Iron Holder |

Optional Extras

| Replacement Part | Description | |

| 1.FH800-03BY | FH800-03BY, FX-8801 Iron Holder | Buy |

| 2.FH800-03SV | FH800-03SV Iron holder with Cleaning sponge and cleaning wire for FX888D | Buy |

| 3. 599B | 599B Dry Tip Cleaner and Holder | Buy |

| 4. FX-780 | ||

| 5. FX-781 | ||

| 6. FX-791 |

| Category | Title |

|---|---|

| How to use | Select Tip Shape |

| How to use | Difference between BC/C type and BCF/CF type |

| How to use | HAKKO N2 system |

| Maintenance | Why doesn't solder flow evenly onto a tip though it is brand-new? |

| Maintenance | If solder does not flow onto the tip... |

| Maintenance | Tip life |

| Maintenance | Why do tips oxidize easily when they are used with lead-free solder? |

| Top Tips | Top Tips for Successful Soldering and De-Soldering Processes |

| Weight | 0.2581 kg |

|---|

You may also like…

- Shop by brand, HAKKO, Product catalogue, Soldering equipment, Soldering iron stands / holders, Spare parts, Replacements for units, Replacements for soldering stations, FX-951

FH200-02, FM2027 & FM2030 Iron Holder w/Sponge Tip Cleaner

Shop by brand, HAKKO, Product catalogue, Soldering equipment, Soldering iron stands / holders, Spare parts, Replacements for units, Replacements for soldering stations, FX-951

Shop by brand, HAKKO, Product catalogue, Soldering equipment, Soldering iron stands / holders, Spare parts, Replacements for units, Replacements for soldering stations, FX-951FH200-02, FM2027 & FM2030 Iron Holder w/Sponge Tip Cleaner

Hakko iron holders are made with temperature resistant materials and feature a non-skid base. Comes with the traditional wet sponge tip cleaner.

SKU: HFH200-02 - Shop by brand, HAKKO, Product catalogue, Soldering equipment, Soldering iron stands / holders, Desoldering equipment, Desoldering Tools, Hot tweezers for stations, SMD rework, Rework tools, Hot tweezers, Spare parts, Replacements for units, FR-701, Replacements for rework stations, FX-889

FX8804 Hot SMD Tweezers

Shop by brand, HAKKO, Product catalogue, Soldering equipment, Soldering iron stands / holders, Desoldering equipment, Desoldering Tools, Hot tweezers for stations, SMD rework, Rework tools, Hot tweezers, Spare parts, Replacements for units, FR-701, Replacements for rework stations, FX-889

Shop by brand, HAKKO, Product catalogue, Soldering equipment, Soldering iron stands / holders, Desoldering equipment, Desoldering Tools, Hot tweezers for stations, SMD rework, Rework tools, Hot tweezers, Spare parts, Replacements for units, FR-701, Replacements for rework stations, FX-889FX8804 Hot SMD Tweezers

Hot tweezers designed exclusively for HAKKO FX-888D, FX-889, FR-701 and FR-702

FX-8804 enables the easy removal of SMD chips and flat packages of up to 25mm

The iron holder clip allows accurate positioning of the tipSKU: HFX8804-02 - Shop by brand, HAKKO, Product catalogue, Thermometers / testing, Units

FG-100B Digital Thermometer

- Automatic measurement to standardize the process

- Automatic temperature measurement

- Measurement counter can be useful for control of changing sensor.

- Fine sensor can deliver accurate measurements.

SKU: HFG-100B - Shop by brand, HAKKO, Product catalogue, Soldering equipment, Soldering iron stands / holders, Spare parts, Replacements for units, Replacements for soldering stations, FR-701, FR-702, FX-888 / FX-888D, FR-701, FR-702, Replacements for rework stations, FR-701, FR-702, Replacements for accessories, Soldering iron stands, FH800 series

FH800-03BY, FX-8801 Iron Holder

Shop by brand, HAKKO, Product catalogue, Soldering equipment, Soldering iron stands / holders, Spare parts, Replacements for units, Replacements for soldering stations, FR-701, FR-702, FX-888 / FX-888D, FR-701, FR-702, Replacements for rework stations, FR-701, FR-702, Replacements for accessories, Soldering iron stands, FH800 series

Shop by brand, HAKKO, Product catalogue, Soldering equipment, Soldering iron stands / holders, Spare parts, Replacements for units, Replacements for soldering stations, FR-701, FR-702, FX-888 / FX-888D, FR-701, FR-702, Replacements for rework stations, FR-701, FR-702, Replacements for accessories, Soldering iron stands, FH800 seriesFH800-03BY, FX-8801 Iron Holder

HOLDER,IRON,FX-888D/888,FX-8805/8801,FH-800

SKU: HFH800-03BY