No products in the basket.

For soldering stations, HAKKO, Product catalogue, Replacements for soldering stations, Replacements for units, Soldering equipment, Soldering irons, Spare parts, Standard

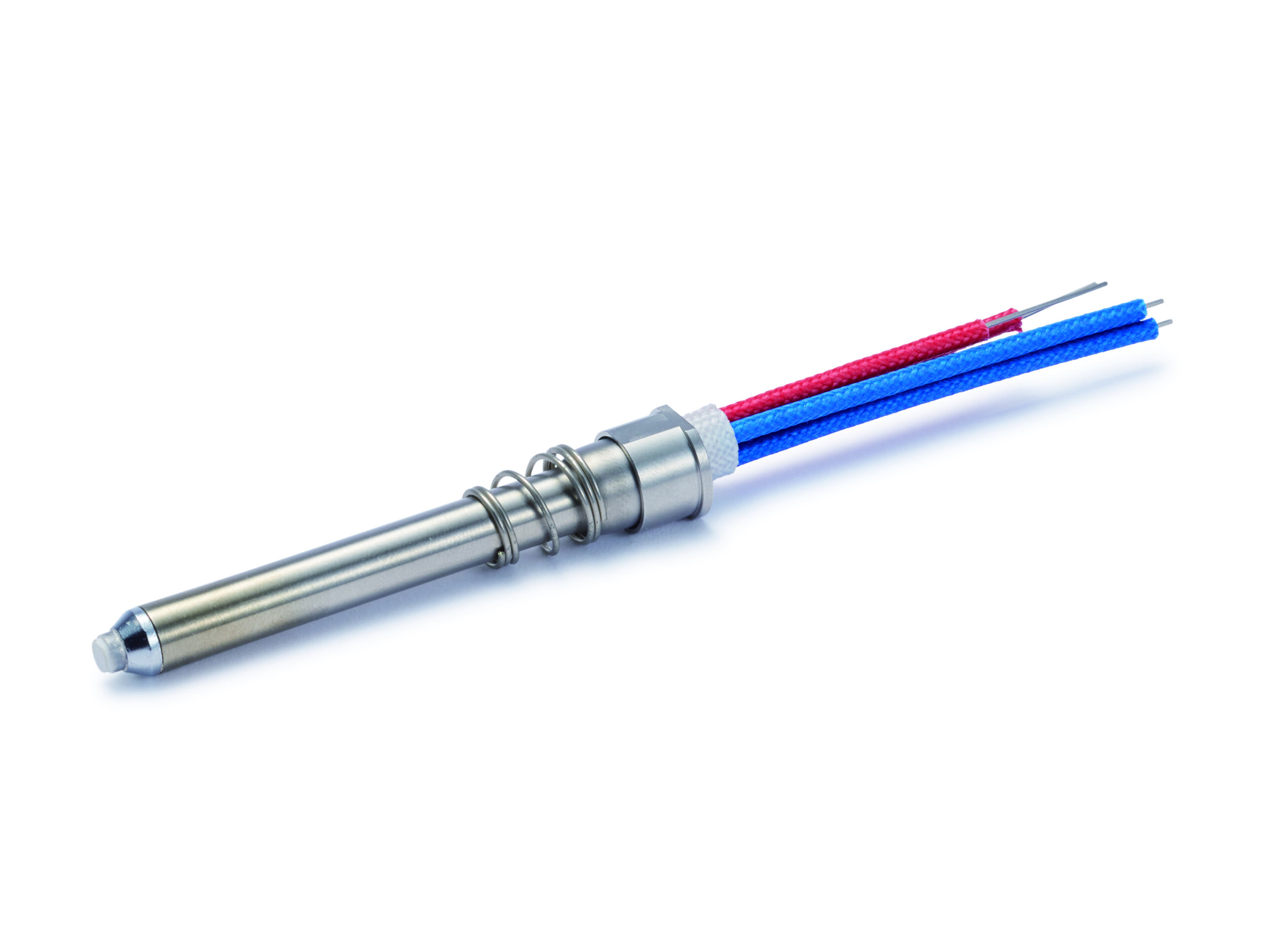

FX8806-811 High Power 95w Soldering Iron Conversion Kit

SKU: HFX8806-811

Availability:

In stock

- 95w Soldering iron for use with the FX888DX soldering station.

- Ideal for use with large components, high heat and high capacity applications.

- Includes a standard T32-D24 Tip – 24 other sizes available.

£146.05 Excl. VAT

In stock

FX8806 Soldering Iron – Includes the T32-D24 as standard.

| Power consumption | 95 W (26 V) |

|---|---|

| Tip to ground resistance | <2 Ω |

| Tip to ground potential | <2 mV |

| Heating element | Ceramic heater |

| Cord length | 1.2 m |

| Total length | 207 mm (with T32-D24 tip) |

| Weight | 40 g (with T32-D24 tip) |

*Total length and weight are measured without cord.

| Compatible with Stations: | |

|---|---|

| FX888DX |  |

| NOT compatible with the FX888D | |

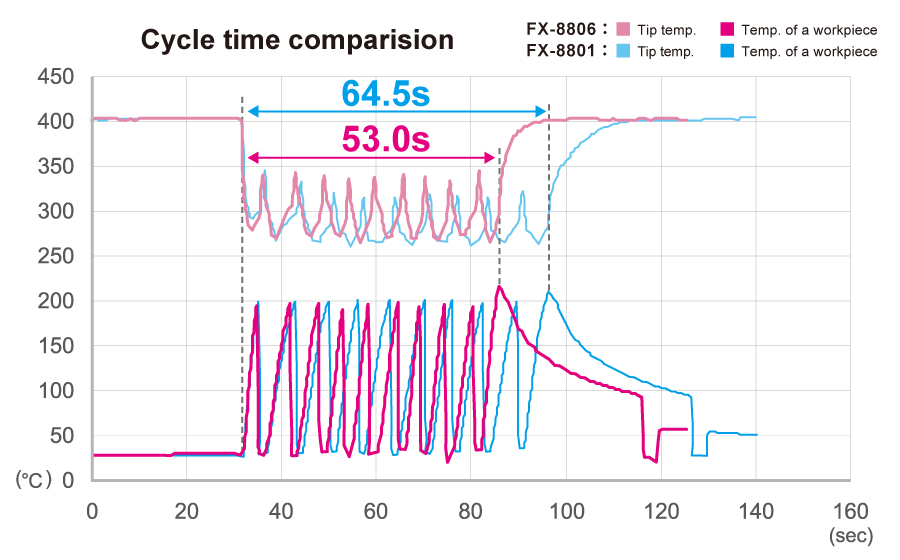

Best-suited for heavy loaded soldering

A new accessory for increase of work efficiency.

95W superb performance heater and new designed tip adopted soldering iron.

- Test criteria:

- Time until the solder portion reaches 200℃ is measured for 10 points.

- Workpiece:

- 6.0mm dia. On the copper plate of 1.5mm thickness

- Spolder:

- Lead-free solder

(Sn/Ag/Cu)

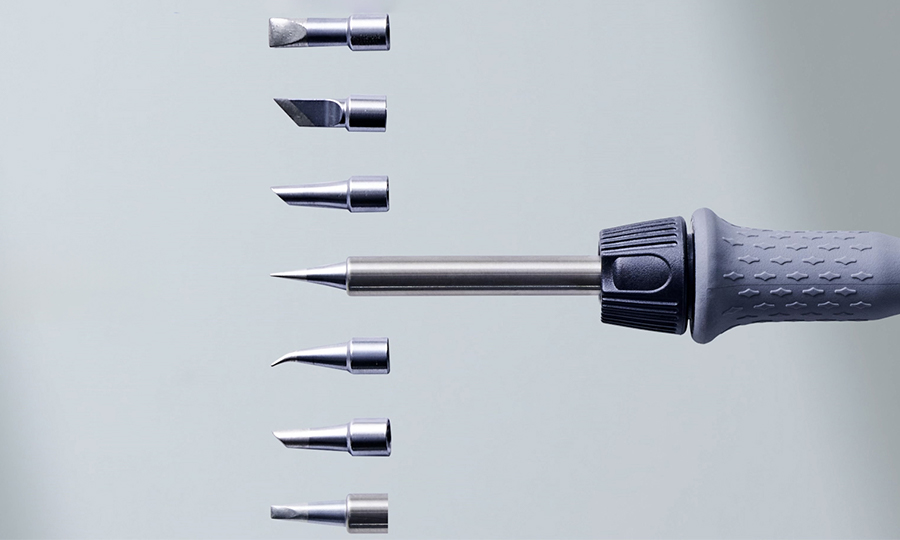

Wide selection of soldering tips

Wide selection of soldering tips from 24 types for your application. T32 series soldering tips

| Part No | Packing List |

No.FX8806-81  | 1. Handpiece + Tip (T32-D24) 2. Instruction manual |

No.FX880-811  | 1. Handpiece + Tip (T32-D24) 2. Iron Holder (FH800 with cleaning sponge + Wire) 3. Instruction manual |

T32 Soldering Iron Tips

T32 tips are used with the FX-8806 Soldering iron used with station FX888DX. The T32 Series includes 24 varieties of tip shape and size covering any soldering or rework application. They are organised into groups by “shape”:

Image | Tip Shape | Description | View Options |

| T32 "B Shape" | Standard conical tips for everyday use | |

| T32 "BC Shape" | This type has a shape like a cone or column cut at a slant, which allows users to select the cut surface size depending on the workpiece. It is used for drag soldering and pre-tinning of lead wires. | |

| T32 "BCM Shape" | This type has a shape like a cone or column cut at a slant, with a hollowed centre to prevent/correct bridging. It is used for drag soldering and correcting bridging. | |

| T32 "C Shape" | This type has a shape like a cone or column cut at a slant. It is used for drag soldering and pre-tinning of lead wires. | |

| T32 "D Shape" | Chisel shaped tips used for line and face soldering as well as narrow pitch. | |

| T32 "I Shape" | Fine shaped tips for small workpieces. | |

| T32 "J Shape" | Angled tip for face and point soldering | |

| T32 "K Shape" | Knife Shape for line, face and point soldering. It is used for soldering at narrow pitches, correction of bridging and drag soldering. |

Hakko FX-8806 Recommended Extras / Options

| Category | Title |

|---|---|

| How to use | Select Tip Shape |

| How to use | Difference between BC/C type and BCF/CF type |

| How to use | Combinations of handpieces and soldering tips for the FM/FX series |

| Maintenance | Why doesn't solder flow evenly onto a tip though it is brand-new |

| Maintenance | If solder does not flow onto the tip... |

| Maintenance | Tip life |

| Maintenance | Why do tips oxidize easily when they are used with lead-free solder |

| Top Tips | Top Tips for Successful Soldering and De-Soldering Processes |