No products in the basket.

For soldering stations, FX-838, HAKKO, Heavy duty, Replacements for soldering stations, Replacements for units, Shop by brand, Soldering equipment, Soldering irons, Spare parts

FX8301-01 High Power Soldering Iron Handpiece

SKU: HFX8301-01

Availability:

Available for order*

High powered 150W soldering iron with high heat capacity

Suitable for use with the FX-838 Station

High Temperature range 200 to 500°C

Best suited for soldering of power-supply boards, heat sinks and shield cases

Applicable also for multilayer boards with micro components

This Soldering Iron does NOT include a Tip (see tips tab)

£95.81 Excl. VAT

Available for order*

| High Power 150W Soldering Station enjoys the various applications from large to fine components. |

| Great thermal recovery improves the soldering environment.(Refer to the graph bellow.) | |||||||

| It allows soldering at lower set temperatures. It can shorten the soldering working time, which minimize concern about the influence of heat on components and tip life.(Refer to the graph bellow.) It is suitable not only for high-power required working condition such as soldering multilayer boards or shield cases but for micro soldering. | |||||||

| |||||||

| Operate at Maximum Temperature of 500 Degrees. | |||||||

| It enables soldering power-supply boards easily because high power 150W hand piece can provide great thermal recovery. | |||||||

| High Power but Safety design of low voltage. | |||||||

| This unit has not only high power but also low output voltage (27V) , which is lower than the world safety output voltage of 30V. | |||||||

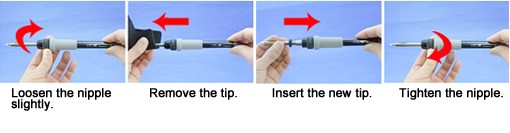

| Easy to replace tips. | |||||||

| Cartridge style Integrated heater makes thermal conductivity improve. Available 20 different shape as replacement, some of which are suitable for fine components. | ||

| HAKKO FX838 replacement Tip List (T20 series) | ||

| Temperature preset mode saves time and effort. | ||

| It allows you to input three frequently-used temperatures in advance and recall them with one push of a button. It saves the troublesome setting condition, tailored to the tip-shape, component and work. |

| Combination of optional handpiece allows use of N2 system. N2 system |

| Great thermal recovery | |

| 150W hand piece provides great thermal recovery, which allows soldering at lower set temperatures to!!minimize concern about the influence of heat on components and tip life. |

| High power saves the working time. |

| The high power shortens the working time. |

– Test Condition

| Test method | Solder at 5 points and measure the time until temperature of the workipiece reaches 250 degrees. |

| Board used | Bakelite board |

| Component | Terminal |

| Tip shape | Shape-1.6D |

| Temperature setting | 340°C |

| Solder | Lead-free solder (Sn/Ag/Cu) 0.5 |

| Model No. | Packing List |

| FX-838 | Soldering iron FX-8301 Handpiece |

| NOTE: | A soldering tip is not included in this product. The tips (T20 series) of desired shape should be purchased separately. |

| Power consumption | 150W (27V) |

| Tip to ground resistance | <2Ω |

| Tip to ground potential | <2mV |

| Heating element | Ceramic heater |

| Cord length | 1.2m |

| Total length | 175mm (with 2.4D tip) |

| Weight | 31g (with 2.4D tip) |

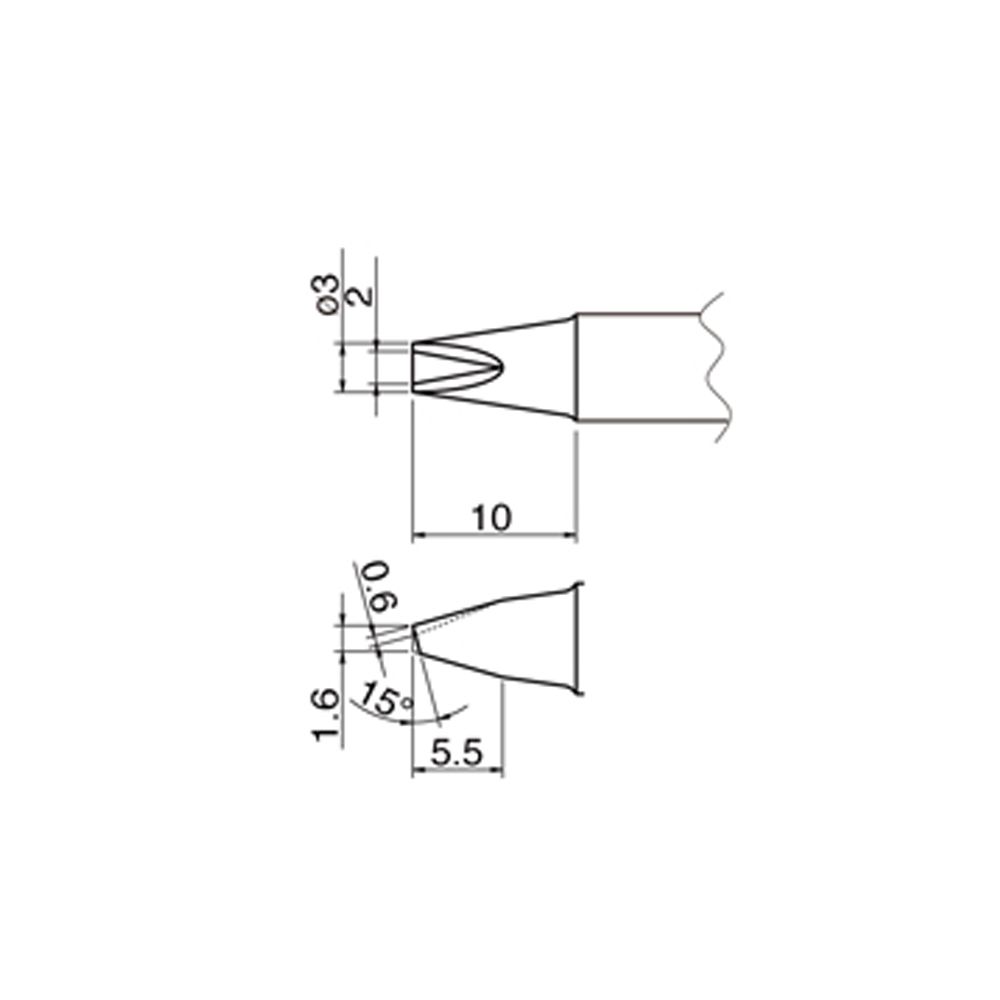

| T20-1610 Concave Soldering Tip 3mm /15° x 10mm | |

| T20-1611 Concave Soldering Tip 3.2mm /45° x 10mm | |

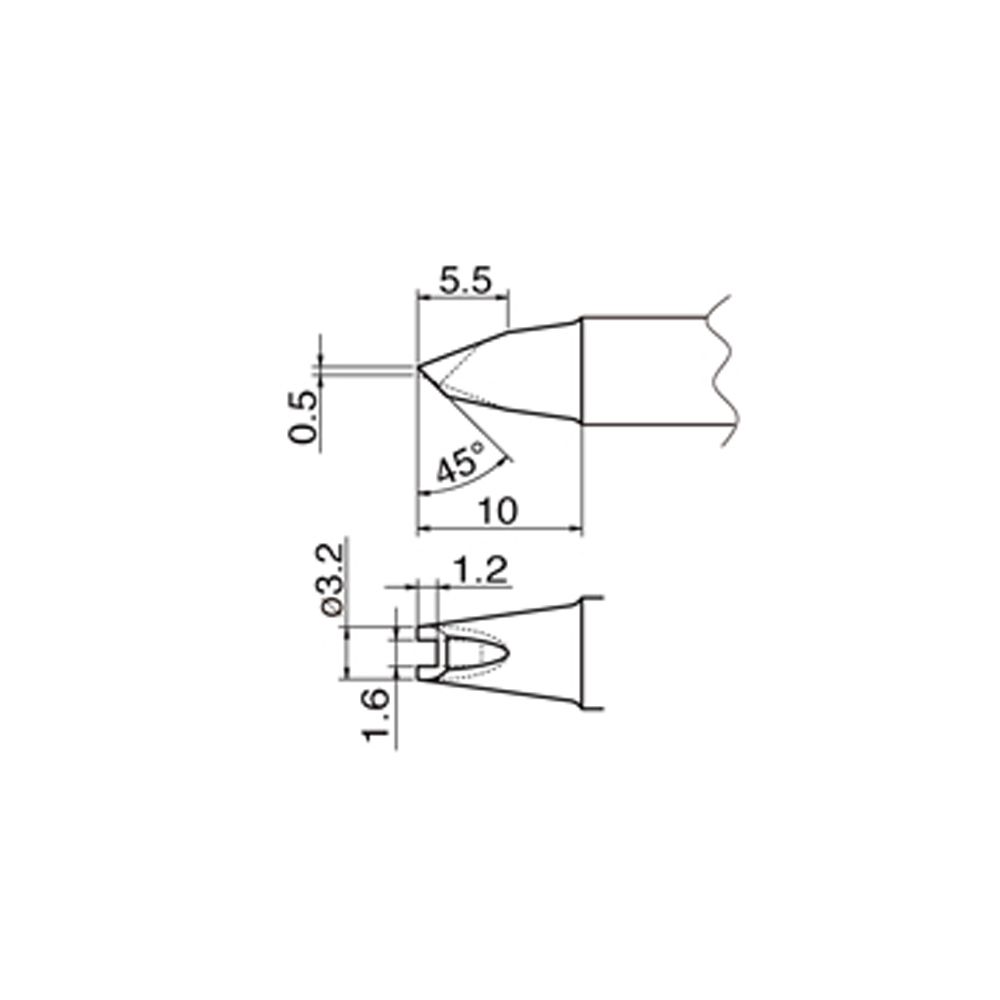

| T20-B2 Conical Soldering Tip R0.5mm x 10mm | |

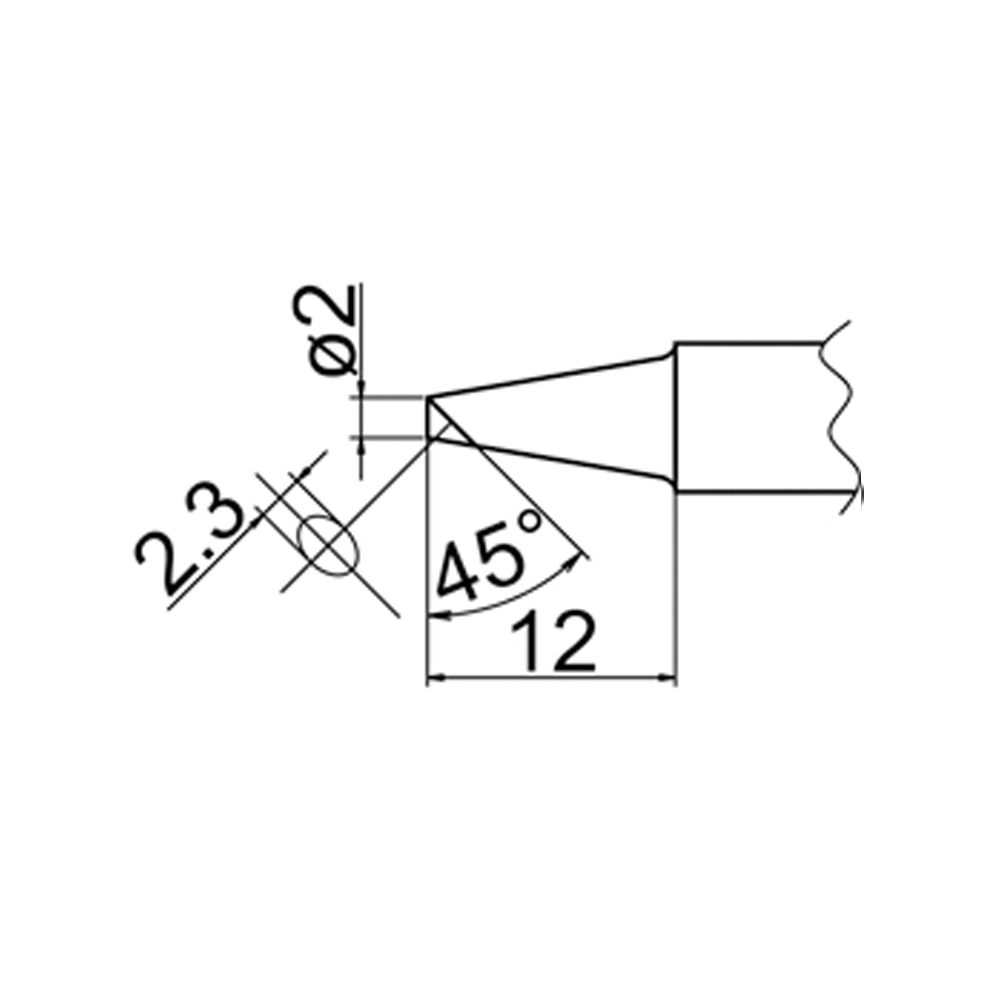

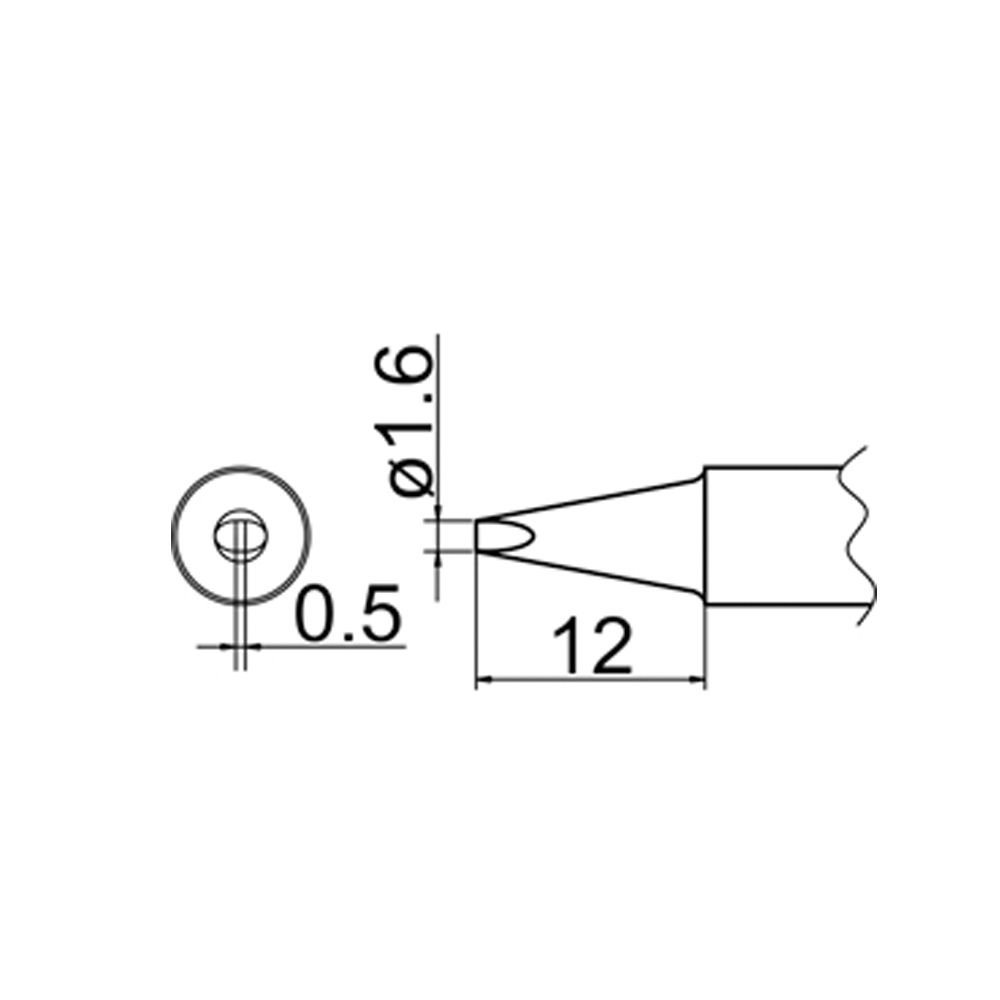

| T20-BC2 Bevel Soldering Tip 2mm /45° x 12mm | |

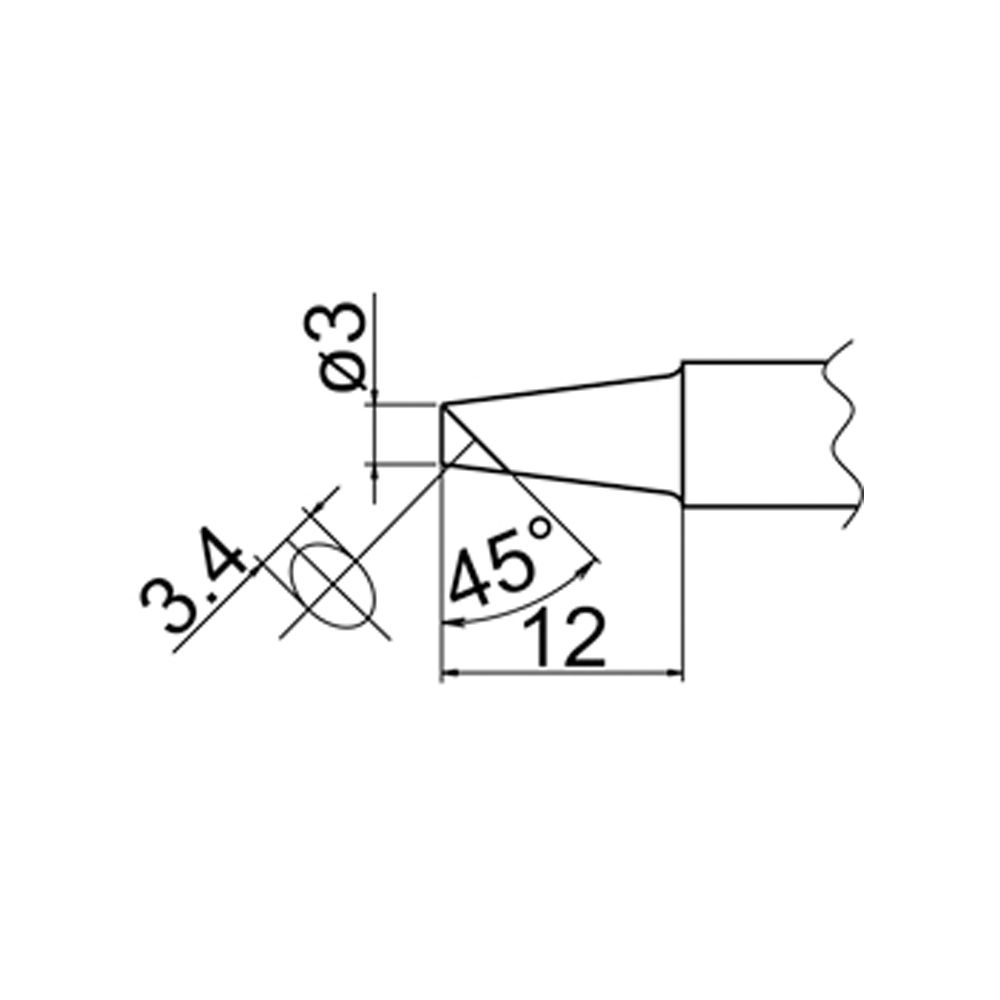

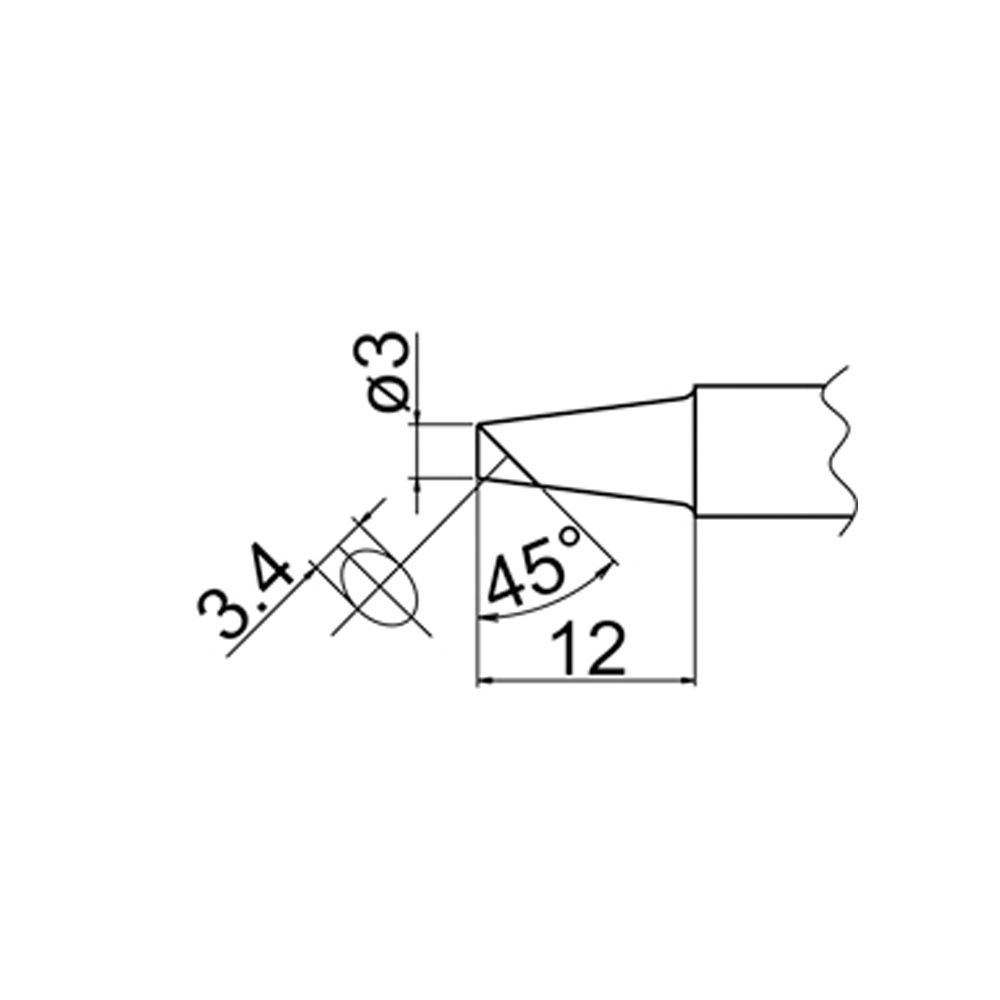

| T20-BC3 Bevel Soldering Tip 3mm /45° x 12mm | |

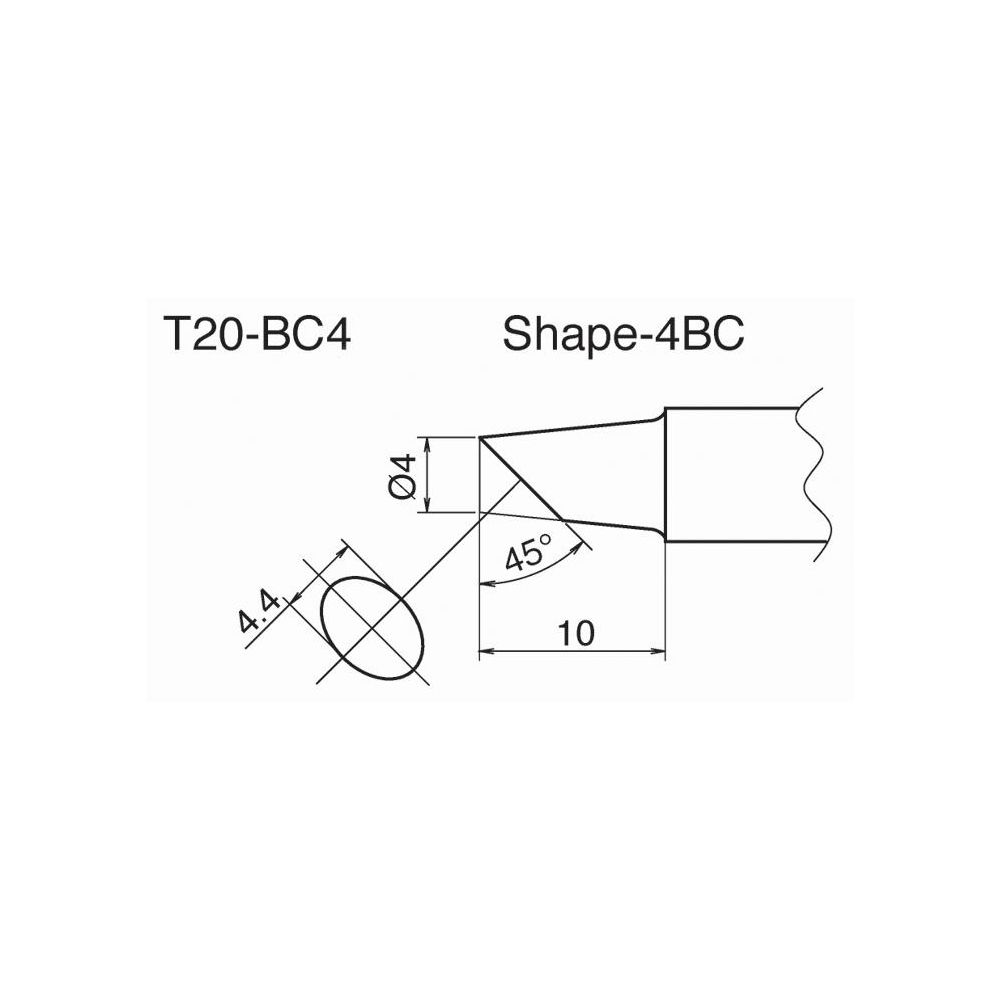

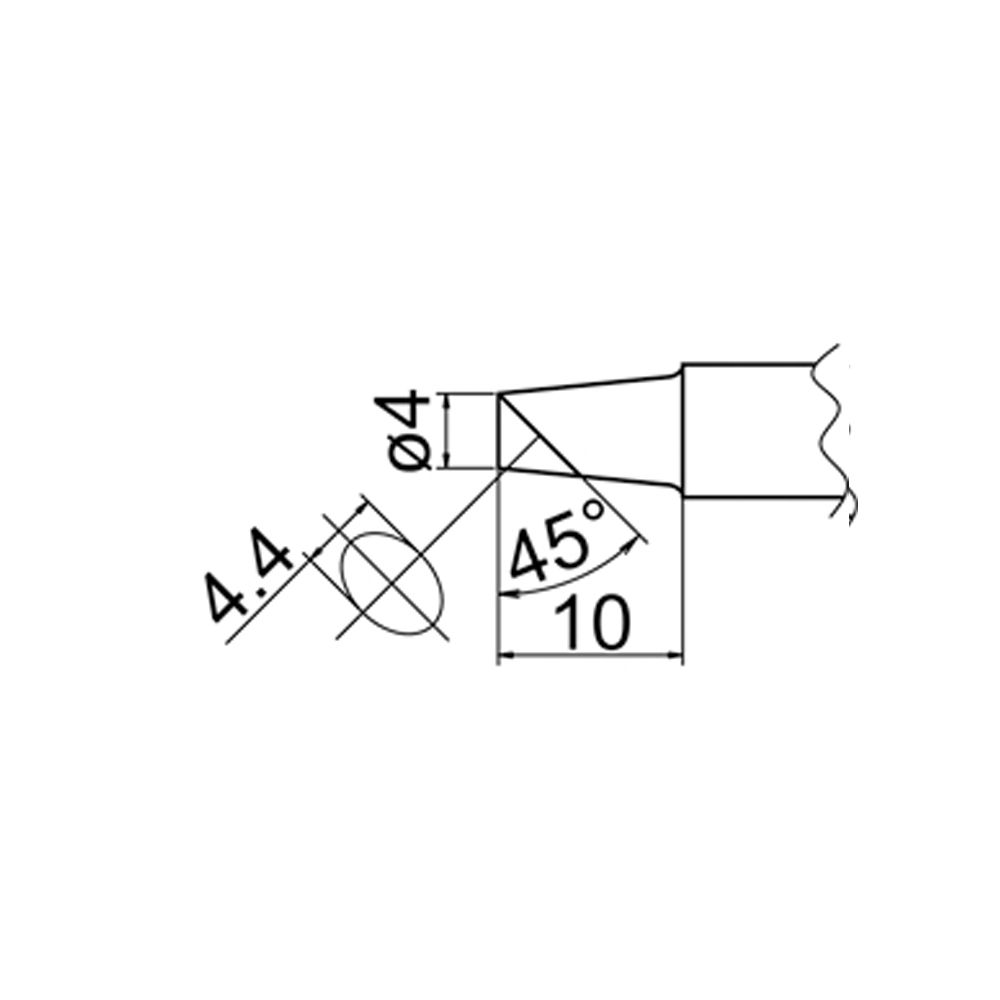

| T20-BC4 Bevel Soldering Tip 4mm /45° x 10mm | |

| T20-BCF2 Bevel Soldering Tip 2mm /45° x 12mm Tinned Cut Surface | |

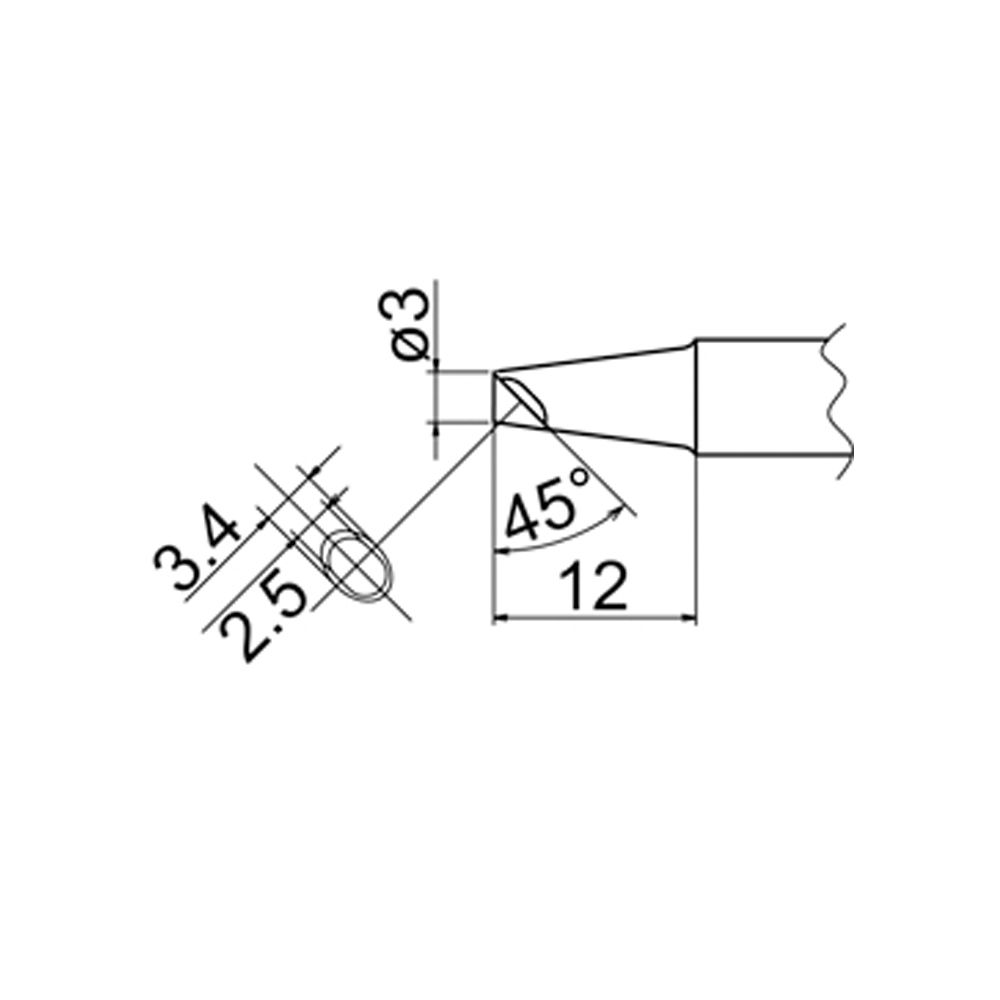

| T20-BCF3 Bevel Soldering Tip 3mm /45° x 12mm Tinned Cut Surface | |

| T20-BCF4 Bevel Soldering Tip 4mm /45° x 10mm Tinned Cut Surface | |

| T20-BCM2 Bevel with Indent Soldering Tip 2mm /45° x 12mm | |

| T20-BCM3 Bevel with Indent Soldering Tip 3mm /45° x 12mm | |

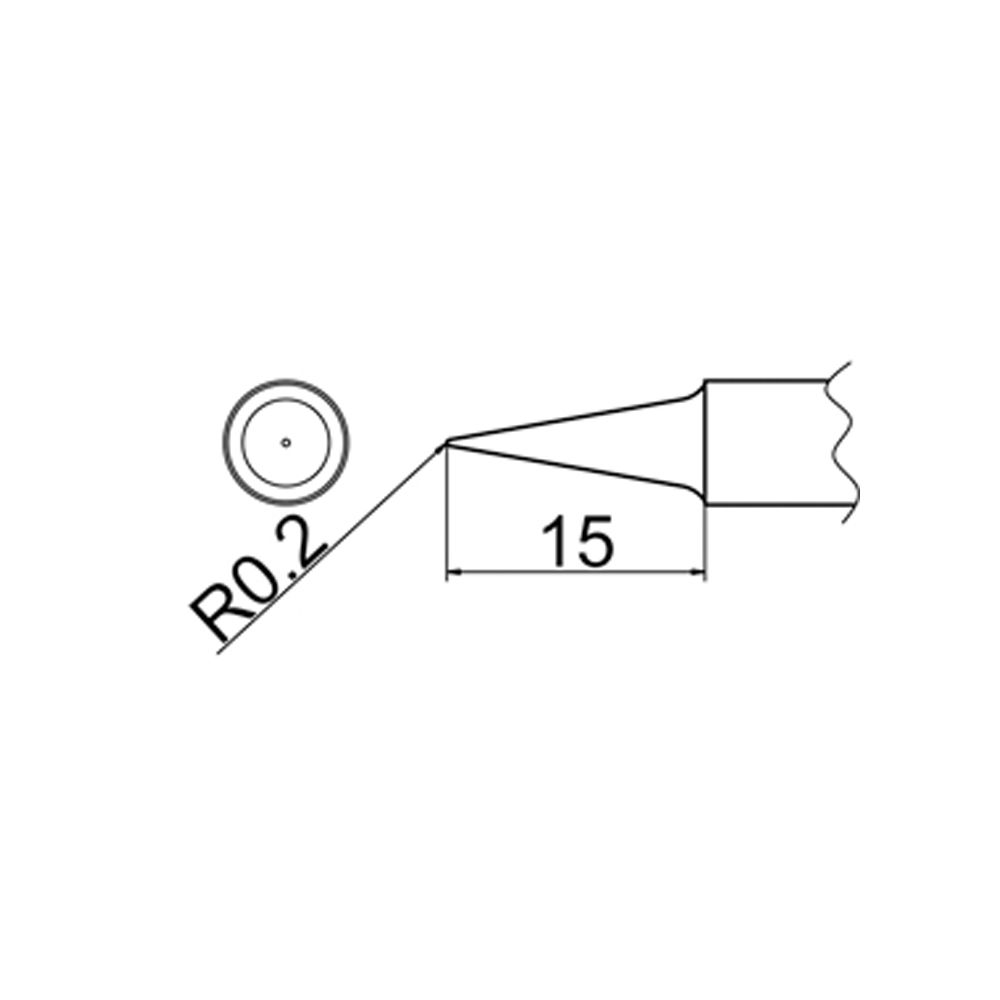

| T20-BL Conical Soldering Tip R0.2mm x 15mm | |

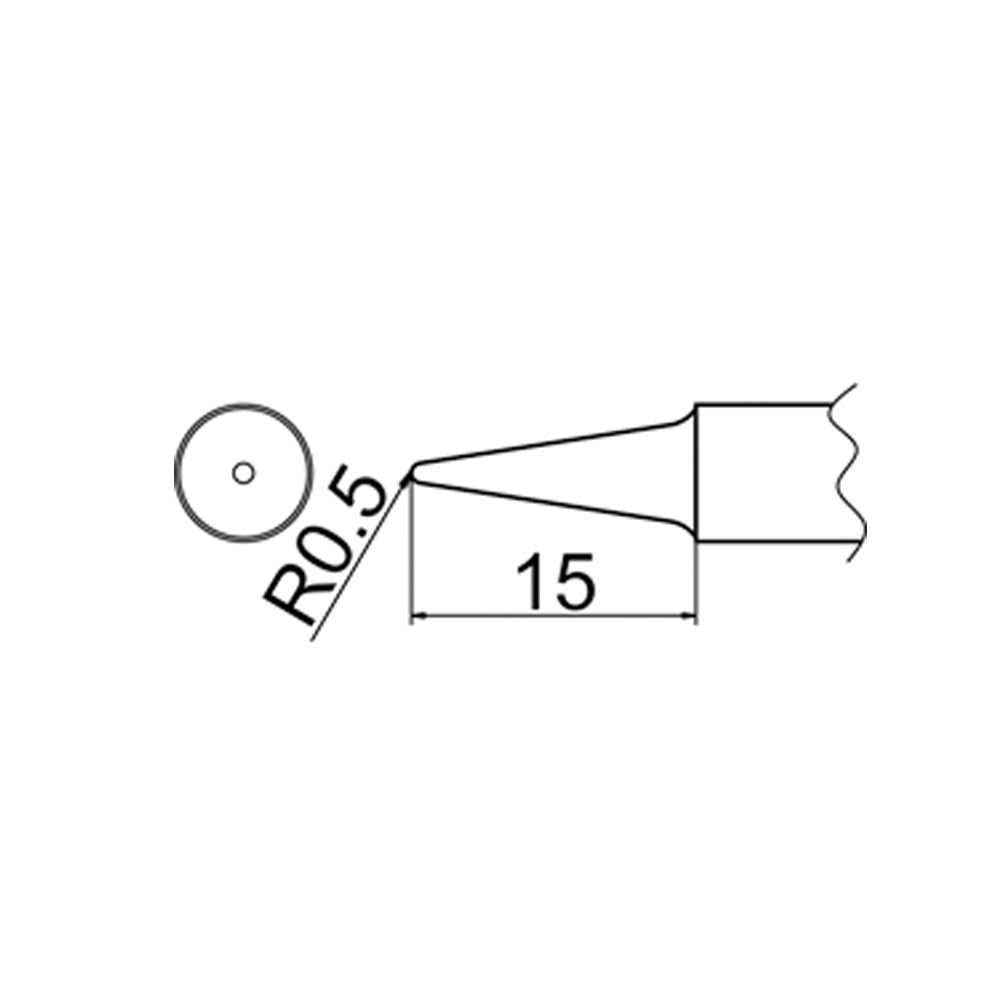

| T20-BL2 Conical Soldering Tip R0.5mm x 15mm | |

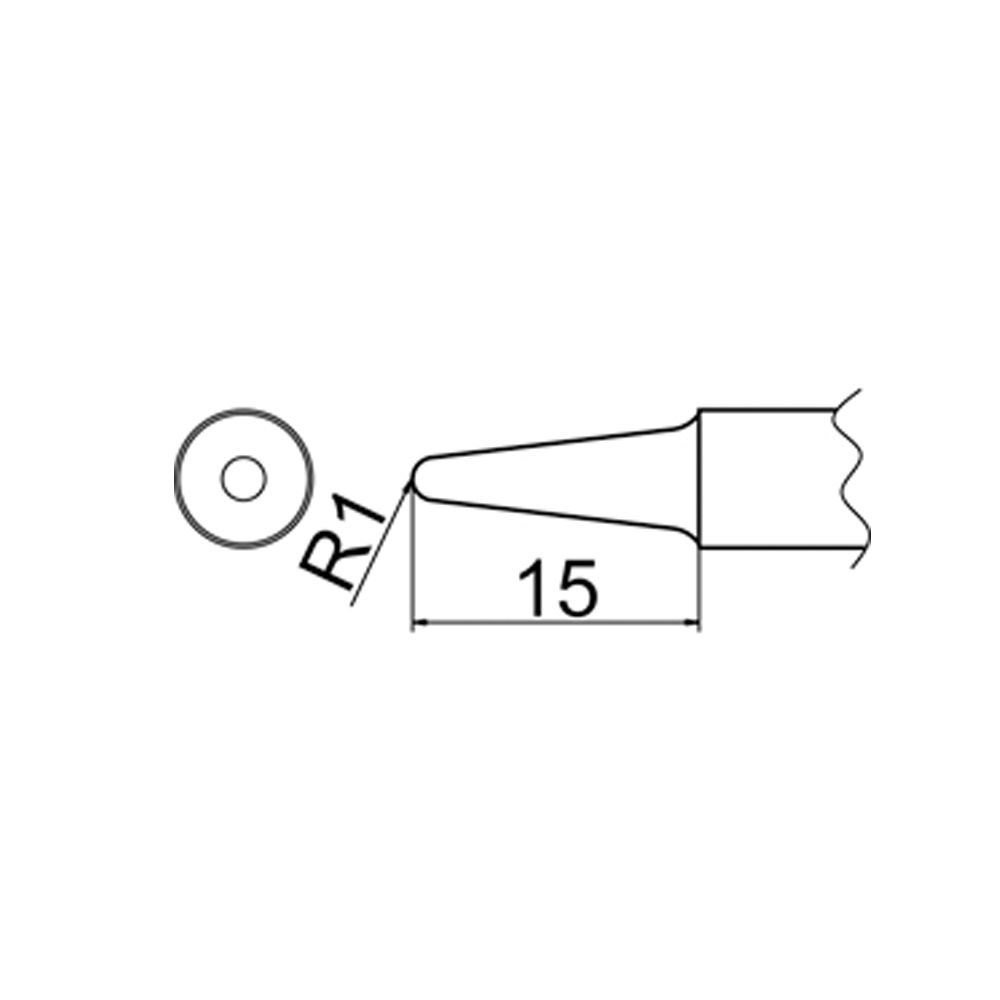

| T20-BL3 Conical Soldering Tip R1mm x 15mm | |

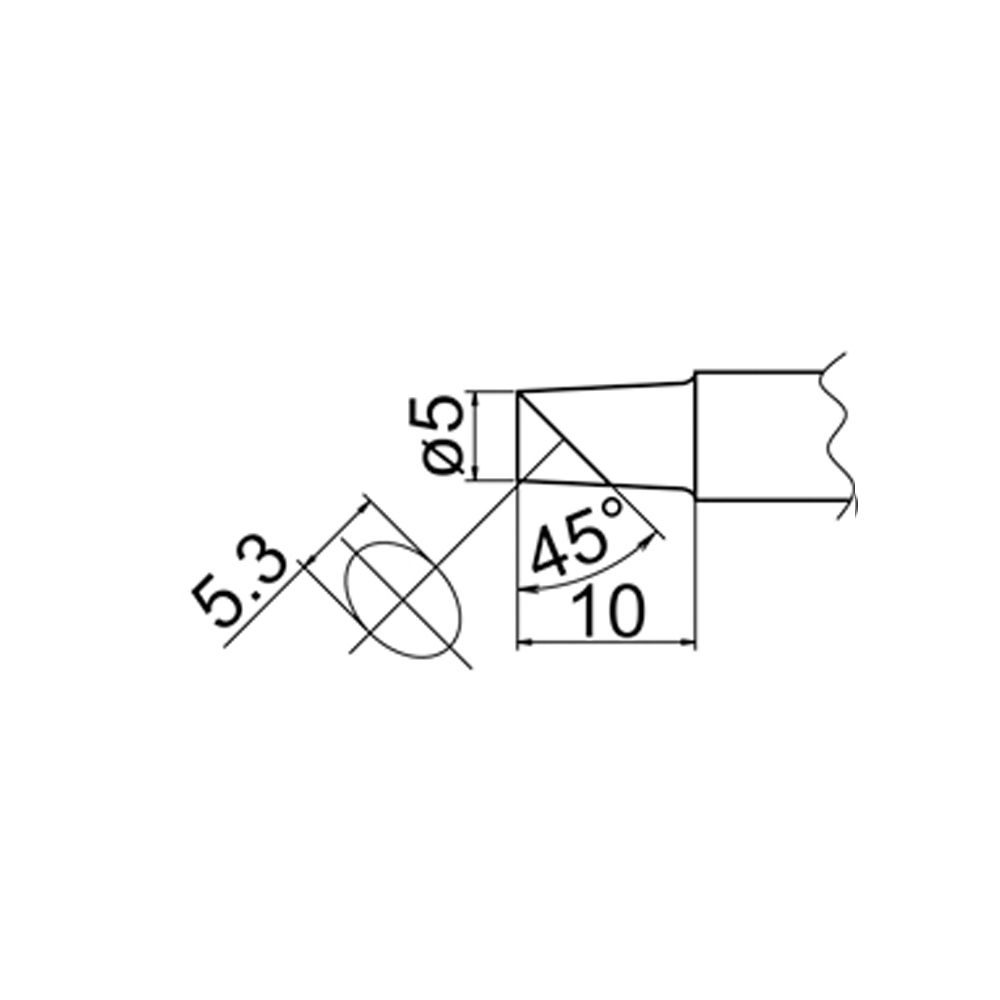

| T20-C5 Bevel Soldering Tip 5mm /45° x 10mm | |

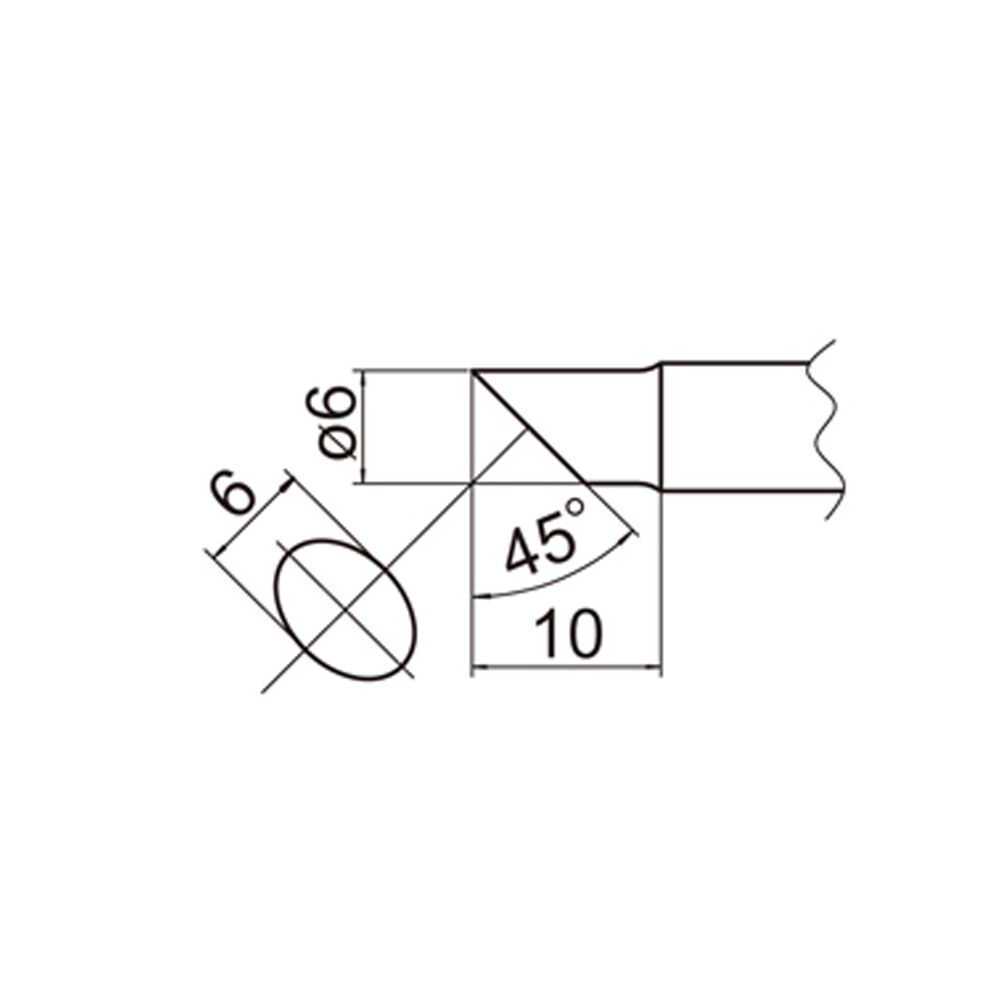

| T20-C6 Bevel Soldering Tip 6mm /45° x 10mm | |

| T20-D16 Chisel Soldering Tip 1.6mm x 0.5mm x 12mm | |

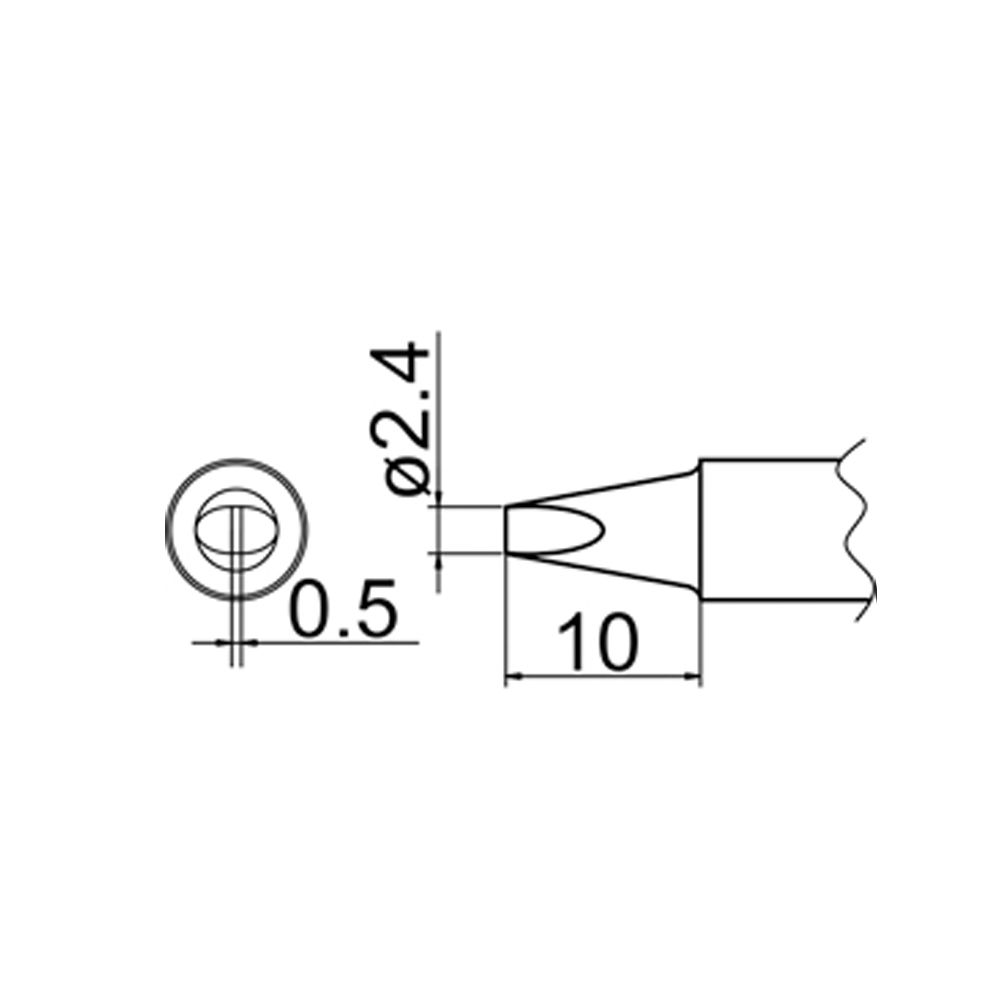

| T20-D24 Chisel Soldering Tip 2.4mm x 0.5mm x 10mm | |

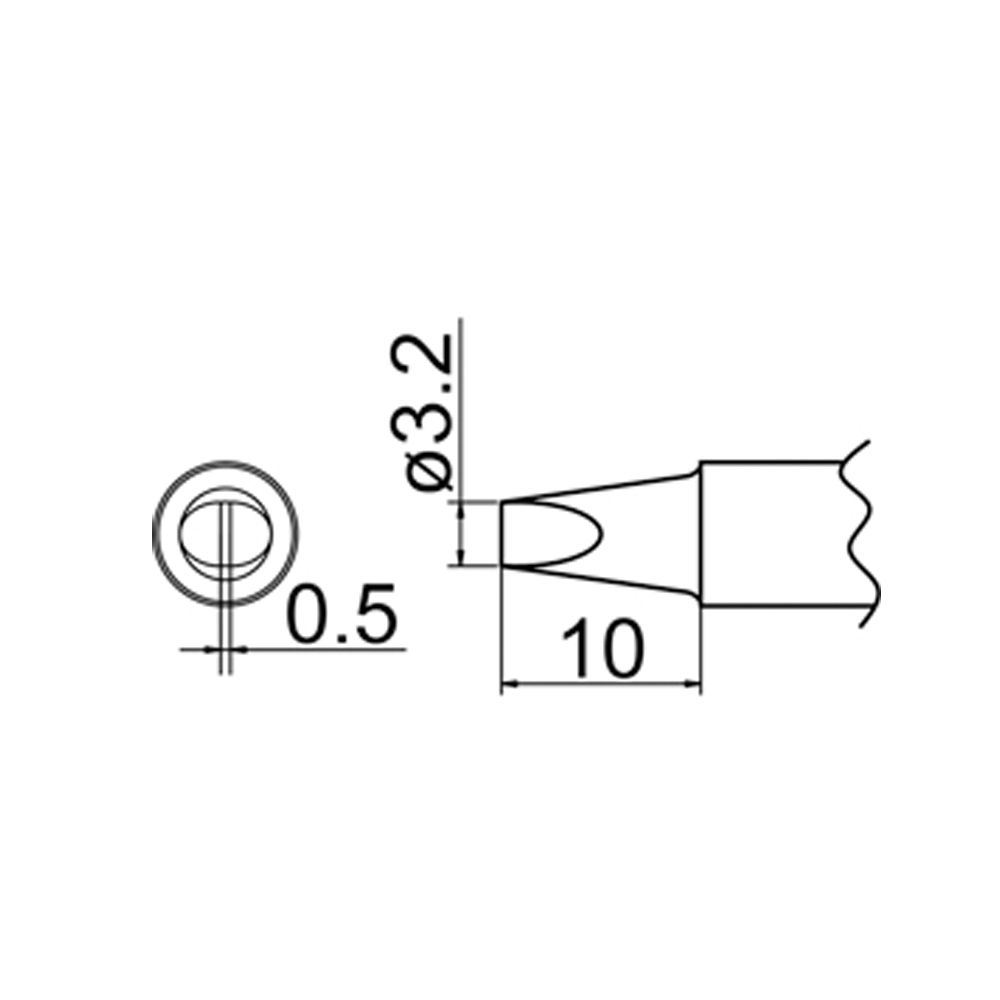

| T20-D32 Chisel Soldering Tip 3.2mm x 0.5mm x 10 | |

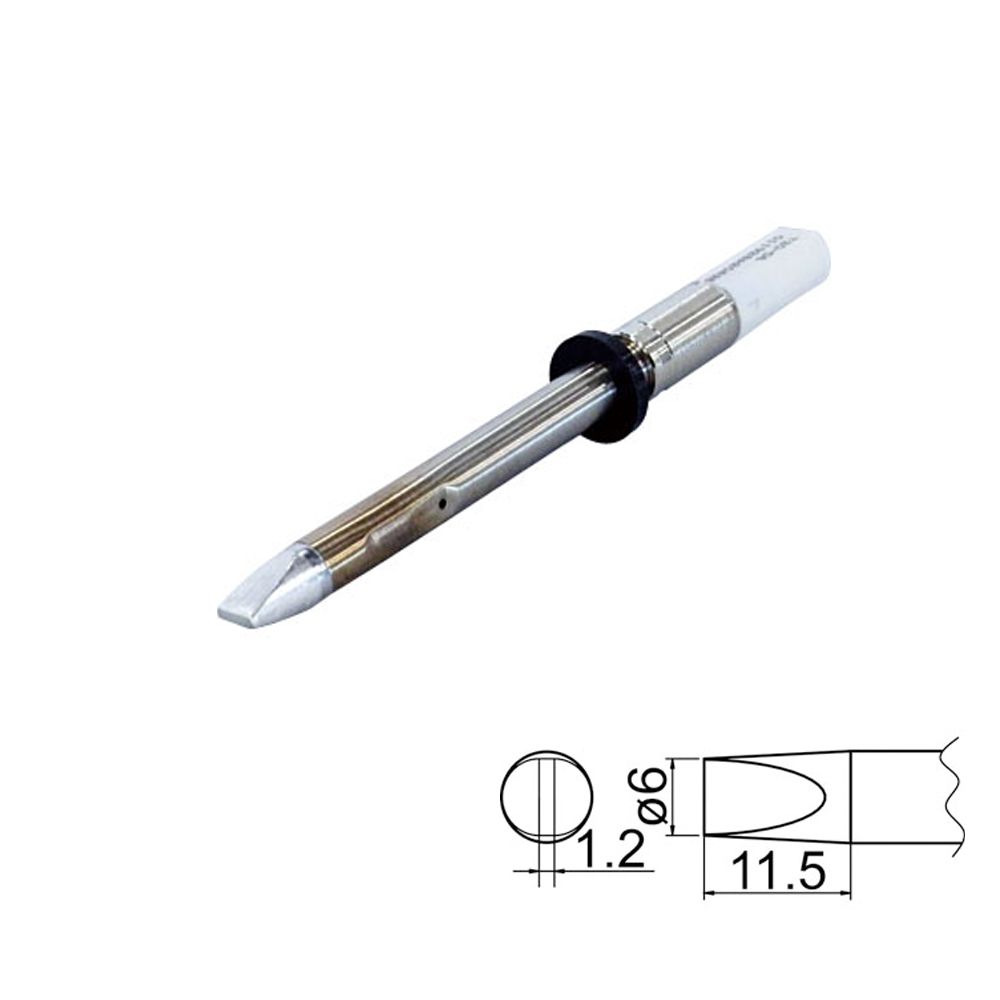

| T20-D6 Chisel Soldering Tip 6mm x 1.2mm 11.5mm | |

| T20-J02 Angled Soldering Tip R0.2 /30° x9mm | |

| T20-K Knife Soldering Tip 5mm /45° x 14 | |

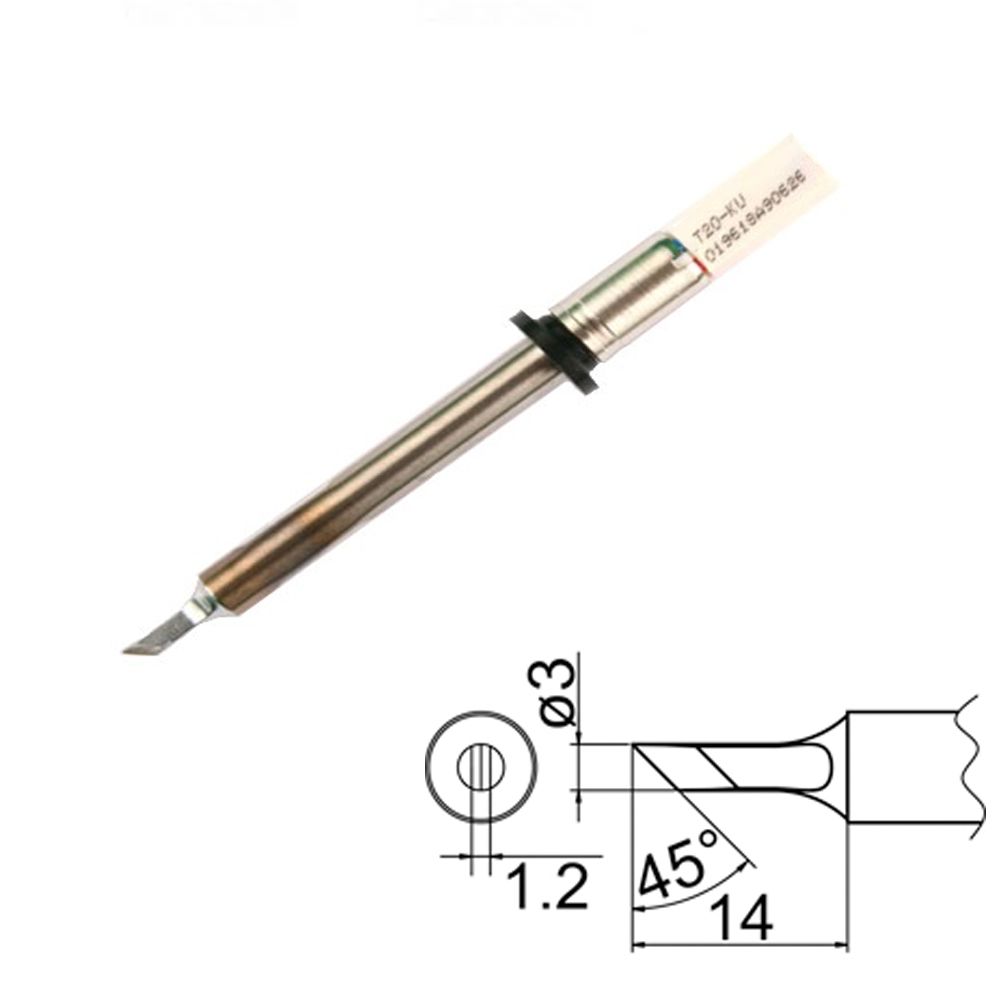

| T20-KU Knife Soldering Tip 3mm /45° x 14 |

Optional / Recommended Extras

| Image | Part Number | Description | Availability |

| Qualitek Solder Wire | Various Available | Buy Now |

| 611-1 | Solder Wire Holder | Buy Now |

| FLU400 | Fluxclene Cleaning Solvent | Buy Now |

| FT-700 | Tip Cleaner and Polisher | Buy Now |

| FA-430 | Air Purifier + Fume Extractor | Buy Now |

| FX8302-01 | Nitrogen Soldering Iron* *Requires Nitrogen Source | Buy Now |

| FX-780 | Nitrogen Generator | Contact Us | |

| FX-791 | N2 Flow Meter | Contact Us | |

| FR-830 | Underboard Heater | Buy Now |

| FX301B | Solder Pot | Buy Now |

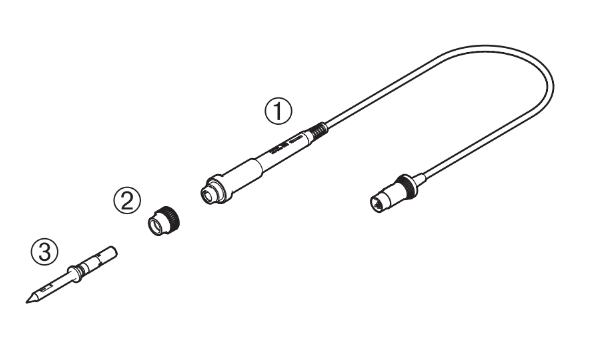

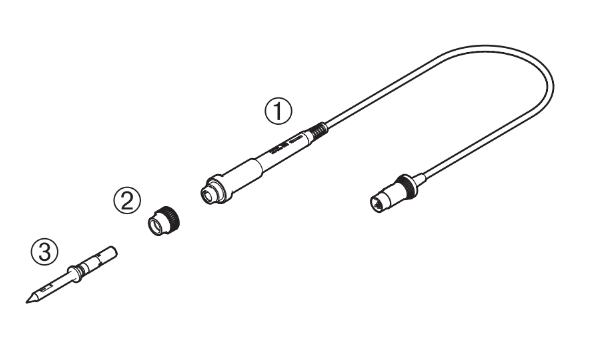

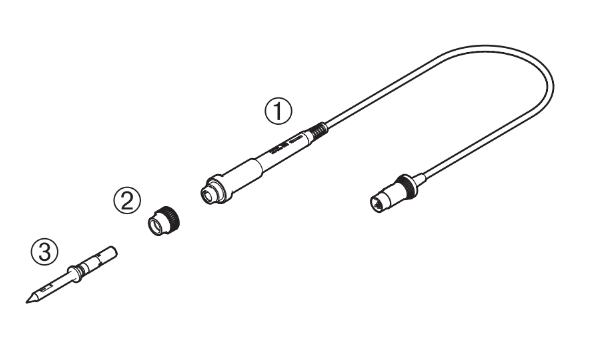

FX8301 Soldering Iron Replacements

| Part | Image | Part Number | Description | Availability |

| 1 |   | FX8301-01 | FX8301 Soldering Iron | Buy Now |

| 2. | B3524 | Nipple | ||

| 3. | T20 Tip | Please See Tips Tab |

Iron Holder FH200-01/2:

| Part Number | Description | |

| FH200-01 FH200-02 | Iron Holder (Inc. Cleaning Wire) Iron Holder (Inc. Cleaning Sponge) | Buy Now Buy Now |

| 1. B3001 | Iron receptacle | Buy Now |

| 2. B2791 | Retaining Clip | Buy Now |

| 3. B3248 | Receptacle Holder | Buy Now |

| 4. B3250 | Back Plate | Buy Now |

| 5. B3252 | Switch Case Assembly | Buy Now |

| 6. B3251 | Base | Buy Now |

| 7. B3249 | Cleaner Base | Buy Now |

| 8. A1519 | Cleaning Sponge | Buy Now |

| 9. 599B-02 | 599 Wire Holder | Buy Now |

| 10. 599-029 | 599 Cleaning Wire | Buy Now |

| Weight | 0.1165 kg |

|---|

You may also like…

- Shop by brand, HAKKO, Product catalogue, Thermometers / testing, Units

FG-100B Digital Thermometer

- Automatic measurement to standardize the process

- Automatic temperature measurement

- Measurement counter can be useful for control of changing sensor.

- Fine sensor can deliver accurate measurements.

SKU: HFG-100B - Shop by brand, HAKKO, Product catalogue, Fume extractors

FA-430 HEPA Compact Fume Extraction Unit

- Compact and Quiet Fume Extraction Unit.

- HEPA filter (High Efficiency Particulate Air Filter)

- Filters out 99.97% of particles greater than 0.3m

- Recommended for quiet laboratory and office

- Duct Set NOT included, please purchase separatel

SKU: HFA430-13