No products in the basket.

Dereks Tech Tips – Issue 16

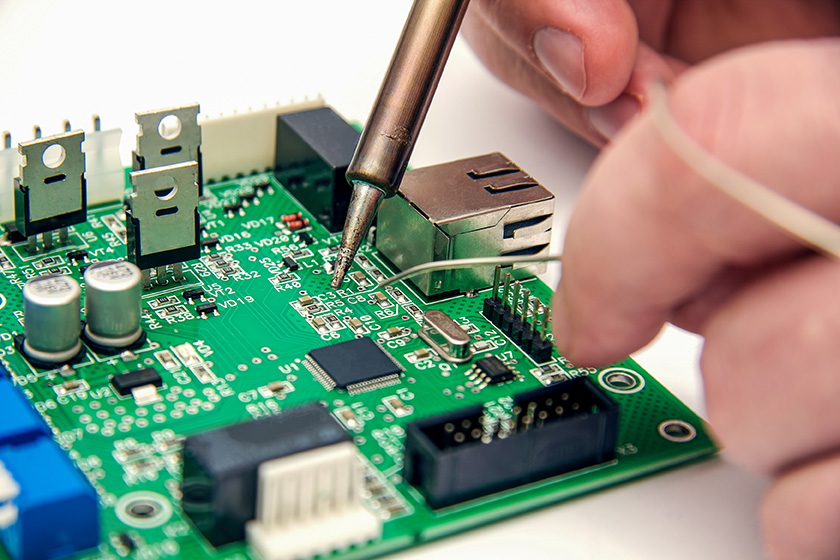

How to Maximise Lead-Free Soldering

In this edition of Hakko Tech Tips, we will be examining the impact of lead-free soldering and explore how to achieve peak performance in your soldering process. Since lead became restricted, there has been a seismic shift to lead-free alternatives such as those containing mostly tin with small amounts of silver and copper. But where former solder had a melting point of 183°C, today’s lead-free solders have melting points in the region of 220°C. Hence, the root cause of the industry’s oxidation problem! Lead-free solder oxidises the tip of a soldering iron up to five times faster than if a eutectic solder were used! With electronic products ever evolving towards increasing miniaturization, multi-function and high integration, there is growing demand for high reliability of solder joints. Approximately 70% of failure in electronic devices originates during the packaging process and is largely due to the failure of solder joints. With the advancement of environmental awareness, lead-free solder joints have become a hot issue in recent years. So, let’s explore how to maximise lead-free soldering in more detail:

How does temperature impact on Lead-Free Solder Joints?

Lead-free solder’s melting temperature is relatively low in comparison to eutectic solder, so the variation of temperature load has a substantial effect on the properties of the solder joint. Today, thermal management materials are commonly used to protect the ambient temperature of an electronic device and ensure reliable operation under harsh end-use conditions. However, temperature can alter the microstructure and internal stress of the solder joint, which is one of the key factors that can contribute to solder joint failure, which is the primary cause of electronic component failure. Therefore, the impact of temperature on solder joint reliability mainly includes aging, thermal cycling and thermal shock.

Why do Soldering Tips and De-Soldering Nozzles oxidize with Lead-Free solders?

Determining the pre-set temperature with little regard for the characteristics of lead-free solder and leaving the tip at the high temperature of lead-free solder’s melting point, speeds up oxidization of the tips. If not checked, the inevitable result of this is reduced life expectancy for the soldering iron tip. Having an understanding of the unique characteristics of lead-free solder and maintaining soldering irons in a clean condition will provide the easiest route to preventing soldering iron tips from oxidizing and prematurely ageing.

How does lead-free solder impact on soldering tips?

In general, the melting point of lead-free solder is 20℃ to 45℃ higher than conventional eutectic solder. Assume, for example, that a soldering iron is set to a temperature of 340℃ to use eutectic solder (Sn-Pb). If the eutectic solder is replaced with lead-free solder (Sn-0.7Cu), the soldering iron must be set to around 380℃, which is close to the maximum temperature for soldering. Such a high temperature also causes shorter tip life (due to oxidation or erosion), carbonization of the flux in the solder and splashing of the flux and solder. Using lead-free solder was decreasing tip life by 4 to 5 times compared with eutectic solder! There have even been cases in which the high melting point affected not only the iron tips but also devices and the PCB. To combat all the negatives of lead-free soldering, Hakko made iron tips compatible with lead-free solder by changing solder plating to tin plating. By incorporating accurate temperature control and excellent thermal recovery rate, you will enable the use of lead-free solder without the need for setting a higher temperature.

What are the benefits of cleaning?

The Hakko 599B cleaning wire greatly contributes to better removal of the black oxide seen predominantly when using lead-free solders. Furthermore, because the cleaning wire will also leave a small amount of solder on the soldering tip, it also helps to provide less exposure to atmosphere and reduces the level of oxidation. There is also no cause for concern regarding any potential damage that might be caused by using the cleaning wires as they are made entirely from brass. The soldering tip is plated with iron and because this is harder than brass, cleaning with these wires does not scratch or cause any damage to soldering tips.

How do I ensure the best performance of my tips when using lead-free solder?

Hakko equipment over the years has proven to be extremely reliable with lead-free solder. Nonetheless, if you want to fully optimise the performance of your tips and equipment, there are few common-sense guidelines that should be followed:

- Always maintain solder tips!

- Turn off the power at the switch when changing solder tips. Failure to do this can cause electrical arcing in the handset, which may compromise the life of the electrical contacts inside.

- Unless using the soldering iron in a continuous workflow process, it is also advisable to switch the power off between applications to reduce the rate of oxidation.

- Make a habit of covering the tip with new solder before placing the soldering iron into its holder during soldering work and ensure that the tip is covered with new solder at the end of a soldering job.

- For De-Soldering units, ensure that the filters are changed on a regular basis. It is more cost effective to replace a low cost filter or filter pipe than a vacuum pump!

- Keep soldering tips clean. Hakko provide a number of cleaning aids to help prevent and remove oxidation from soldering iron tips.

Sustaining a daily maintenance regime in a clean, dry and well-ventilated area will ensure that your Hakko equipment stays in tip top condition. For Soldering Stations, a periodic check of leak voltage, tip-to-ground resistance and tip temperature are advised. The reason for this is that even if the insulation resistance is measured, it will not show the safety at the device side directly because the inside is insulated with a transformer. To prevent device damage and soldering failure, periodically perform these inspections either daily or weekly. Hakko’s Soldering Iron Tester, FG-101, can measure leak voltage, tip-to-ground resistance and the tip temperature (insulation resistance cannot be measured).

Do Hakko Tips require calibration – if so, how often?

It is good practice for all soldering tips to be calibrated, especially when using lead-free solders. Despite any technology to the contrary, the build-up of black oxide can insulate the heat from the soldering tip to the component/PCB. As a result, daily use of a digital thermometer such as Hakko’s FG100B is advisable. The process is also recommended when a soldering tip is changed. Hakko’s FG100B Digital Thermometer provides accurate automatic measurement of soldering iron tip temperatures and includes a new AUTO HOLD feature. With this function, the measurement will end automatically once the tip temperature is stabilized, which minimizes individual differences in measuring temperature. When not in use for three minutes, the auto shut-off feature turns the thermometer off to preserve battery life. The design of the thermometer allows for easy measurements from right or left handed operators and the temperature display allows the reading to display in either °C or °F.

Additionally, the FG100B features a low battery alarm as well as a burnout alarm, which signifies a sensor burnout. The product’s design allows for easy access to sensors for quick and easy sensor replacement. There is also an optional temperature probe to measure solder pot temperatures.

Is it possible to restore Hakko soldering tips/desoldering nozzles?

This is a question we get asked a lot, and the simple answer is yes. The Hakko FT-700and FT-710 tip polishers provide a fast and easy way to renew your soldering tips by keeping them clean and free from oxidation, they are also highly effective for lead-free solder. Both tip polishers remove tip oxides, debris, and excess solder without damaging the tip plating, and can be used in conjunction with Hakko’s FS100 Tip Cleaner, a lead-free chemical paste. So, what are the differences between the two tip polishers? The FT-700consists of two spinning polishing brushes and the FT-710 has counter-rotating brushes that are activated when the tip is pressed into the receptacle chamber.

To restore new life to your soldering iron tips, simply dip the soldering tip into the FS-100 paste to re-tin the tip, then insert the tip between the spinning brushes of the FT-700 or into the counter-rotating brushes of the FT-710 to remove all melted paste. Finally, tin the tip with the solder currently being used, before placing the iron into the holder.

This quick and easy process is simple to adopt into your soldering routine to enjoy the benefits of a clean, oxidation-free tip, especially when working with lead-free alloys.

We welcome feedback from our customers and potential new customers, so please do talk to one of our team if you have any questions. Look out for next month’s Hakko Tech Tips where we will be providing more advice on how to get the best performance from your Hakko equipment.

For further information about Hakko, please visit www.hakko.co.uk.