No products in the basket.

Dereks Tech Tips – Issue 13

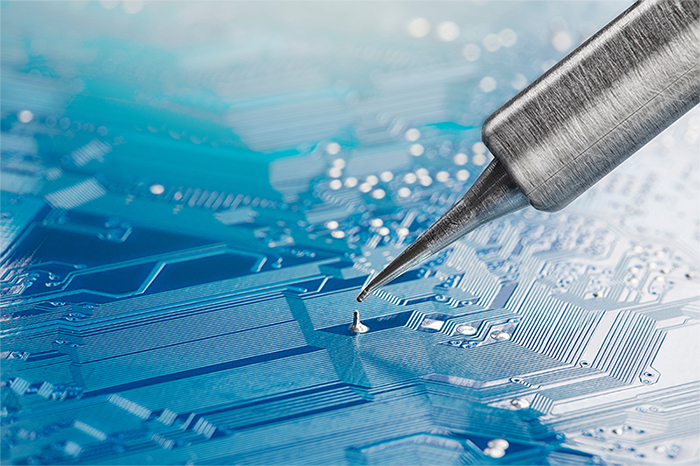

Speed Up Your Workflow with The Right Soldering Tip

Tip selection can often be a personal preference, but as we all know, there is always room for improvement and that is where the Hakko range of tips can really help make soldering more efficient, affordable and even increase productivity. There are several factors to consider when choosing the most appropriate tip for your application, such as the type of soldering to be done, the Hakko soldering station being used, the tip series required, and the optimum size and shape required. To help you pick the best tip for your application, let’s look at the different factors involved.

Tip Size

There are numerous benefits to getting the right-sized tip. Firstly, heat will be more efficiently transferred to the workpiece, which offers easy wetting by the solder. When wetting is easy, the set temperature of the soldering station can be programmed to a lower temperature, which in turn prevents tip oxidation. This will consequently prolong the service life of the tip and keep costs down in the long-term. The size of the tip changes the contact area with the workpiece and the contact area determines how efficiently heat is transferred to the workpiece. So, what size will transfer heat the most efficiently?

Larger sized tips have a higher thermal capacity and will maintain their temperature better when working on large contact areas or applications with a high heatsink effect. However, they may be too big for many applications. Smaller tips are more versatile and could be easier to use in small, intricate areas. Unfortunately, they will tend to cool down when presented to a large contact area. Selecting an incorrect sized tip is a common mistake that is easy to make. Choosing a tip that’s too small will result in insufficient heat being transferred. Conversely, choosing an oversized tip could result in damage to the PCB and or component. As a rule of thumb, selecting a tip with the largest amount of thermal mass at the appropriate size will, importantly, ensure temperature stability of the tip during soldering and facilitate operation at a lower temperature set point. Potentially, this could also reduce the time taken to produce a good quality solder joint. For instance, a lower set point for a shorter period will result in significantly reduced tip oxidation and longer tip life. Therefore, always select a tip that closely mirrors the physical size of the solder joint to be produced and has the highest thermal mass allowable for the application.

Tip Shape

Now, let’s study how to select a tip with the appropriate shape by using the Hakko T15 series as an example. The T15 soldering tips are available in 13 different shapes and in a large variety of sizes, all of which are compatible with Hakko’s FX951, FX952, FM203, FM204 and FM206 soldering stations.

Shape BC/C

The BC/C tips have a shape like a cone or column, cut at an angle. There are various sizes available which allows the user to select a size that closely matches the soldered joint to be produced. These are ideally suited for drag soldering and pre-tinning of lead wires. The BC has a tapered shank and the type C is cylindrical but both are cut at an angle. Regarding the heat capacity of these tips, most of the BC tips have a shorter shank. Therefore, although two tips (BC & C) may have the same tip diameter it is likely that the BC version will have a larger thermal mass. There are 12 x BC/BCM and 5 x C type Tips available.

Shape BCM

The BCM series prevents bridging from occurring when drag soldering. This is because of the greater force exerted by the surface tension of the solder in the indent. Thus having a lesser tendency to leave solder as a bridge. There are 2 x BCM Tips available.

Shape B

Shape B is an all-round type, which can be used from any direction and is easy to hold at any position, making it possible to solder any surface from small to large. However, it unlikely to be suitable for applications requiring a large contact area. There are 5 x B type Tips available.

Shape D

Shape D is a very versatile tip, shaped like a flat-blade screwdriver. It is capable of soldering by applying the tip in 2 ways: line and face. You can select the size of tip suitable for the workpiece and it can be used for most soldering applications. There 12 x D type Tips available.

Shape I

Shape I has a thin conical end and is an ultrafine tip, which is best suited for soldering at narrow pitches, etc.

It is the best tip for soldering small components and for repairing high-density PCBs. There are 3 x I type Tips available.

Shape J

Shape J differs from Shape B and I as it has an angled tip. It is capable of soldering by applying the tip in 2 ways: face and point. These properties make it ideal for intricate soldering, even in heavily populated areas of the PCB. There are 6 x J type Tips available.

Shape K

Shaped like a knife, Shape K is even more versatile! It is capable of soldering by applying the tip in 3 ways: line, face and point. It is used for soldering at narrow pitches, correction of bridging and drag soldering. There 4 x K type Tips available.

SMD: Shape Quad

Shape Quad tip is capable of heating numerous pins on a four sided device simultaneously so can be used for both production and rework applications. There are 10 different sizes available.

SMD: Shape Tunnel

The SMD: Shape Tunnel tip is capable of heating numerous parallel pins simultaneously and can be used for both production and rework applications. There are 10 different sizes available.

SMD: Shape Spatula

There are four different sizes of Spatulatip available (up to 40mm wide) and these can be used for heating numerous pins simultaneously. They are suitable for the soldering of Flexible PCB, RFI shielding cases, and connectors. There are 4 x Spatula Tips available.

Shape R

Shape R is similar to a D-series tip in construction but has a machined tip to accept chip components. This allows the soldering and removal of these devices using one tip. Because the component fits into the groove it allows simultaneous soldering/de-soldering of both soldered joints. There are five different sizes of this tip available.

Shape SB

Shape SB is the perfect solution for fine-pitch soldering. There are 5 x SB type Tips available.

Special Applications

For special applications, 2 key Shape D products, T15-1603 (Shape-Long reach chisel) and T15-1605 (Shape-Long reach bent chisel) can be used in 2 ways of line and face. Both offer an excellent solution for fine-pitch soldering.

One of the most important things to bear in mind for effective tip selection, is that even though two tips are similar in size, one may have a greater thermal mass, which will greatly contribute to improving the soldering environment. Therefore, select a tip with the highest thermal mass even if the physical size is the same. If a small reduction in temperature is seen the set temperature can be kept lower. This will inevitably lead to a reduction in the cycle time to produce a soldered joint and increased productivity. It is usually unnecessary to programme the solder station to an excessively high set temperature.

We hope you found our advice on tip selection useful and that it has highlighted the versatility and variety of tips available from Hakko for even better performance, reduced cost and improved work-in-progress. Look out for Hakko Tech Tips next time, and in the meantime, feel free to contact us for any advice with your soldering or extraction equipment questions.