No products in the basket.

HAKKO, Pre-heaters, Product catalogue, Shop by brand, SMD rework

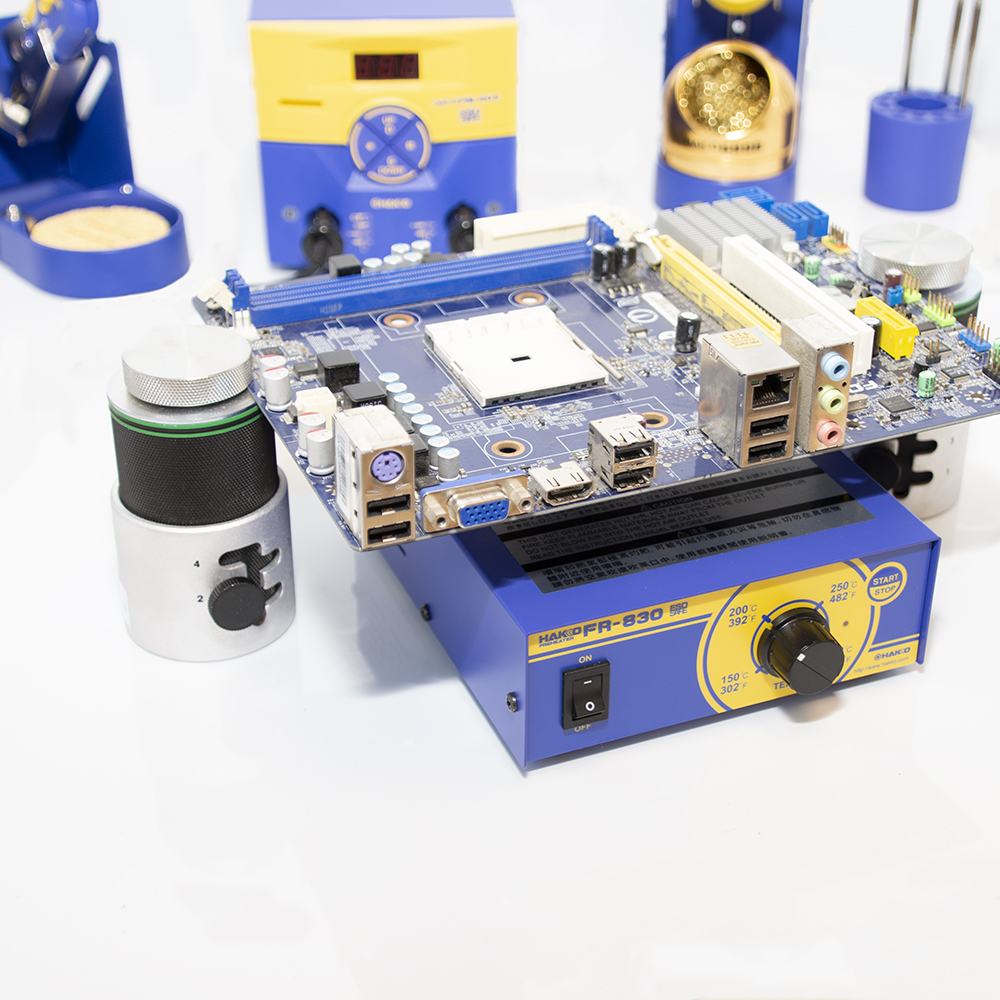

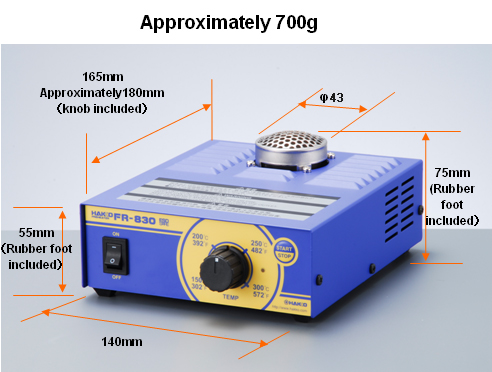

FR-830 PCB Underboard Heater

SKU: HFR830-13

Availability:

In stock

- Compact pre-heater best suited for heat processing on localized areas

- Featuring quick heatup and less variations in temperature

- Best suited for pre-heating of multi-layer PWBs

£427.36 Excl. VAT

In stock

Features

| Using the optional equipments |

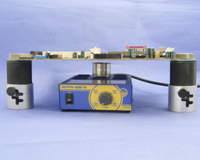

| HAKKO FR830-13 PCB Underboard Heater + Omnivise C1390C (2 used) (Rework system) +Extension pipe/with backflow prevention lid B3263 (option)

|

| Set example |

| HAKKO FR830-13 PCB Underboard Heater + SMD rework station HAKKO FR803B (discontinued) + Rework fixture C1392B* + Omnivise C1390C* (2 used) *Rework system |

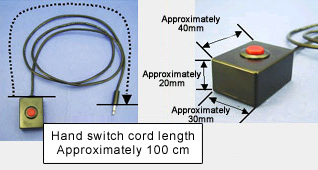

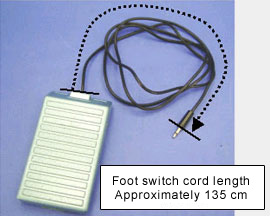

| Various types of switching! [Hand switch][Foot switch] can be connected. |

| Hand switch | Connection cord length: Approximately 100 cm Switch size: Approx. 30mm (W) / 40mm (D) / 20mm (H) When using the hand switch, switching is not possible on the main device.

|

| Foot switch | Connection cord length: Approximately 135 cm When using the foot switch, switching is not possible on the main device.

|

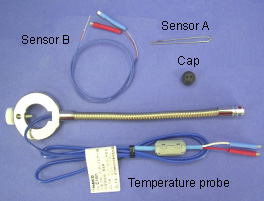

| Controlling the temperatures of Hot Air Rework System and workpiece using the Temperature Probe Measure temperatures of Hot Air Rework System and workpiece using the Temperature Probe for Hot Air Rework System (No. C1541) and thermometer (HAKKO FG-100/HAKKO FG-101) to protect the workpiece. |

|

|

* Please refer to above values, which vary depending on soldering condition.

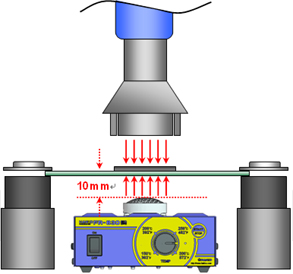

| Measuring condition |

| Hot air temperature 300°C A gap between the hot air outlet and the PWB for 10mm Attach sensors to top/under sides of P.W.B and measure temperature. |

Usage/Applications

| Please keep a gap between the hot air outlet and the PWB for more than10mmto allow the air to flow. When there is not enough space for the air to flow, the fuse may blow up. |

|

| |

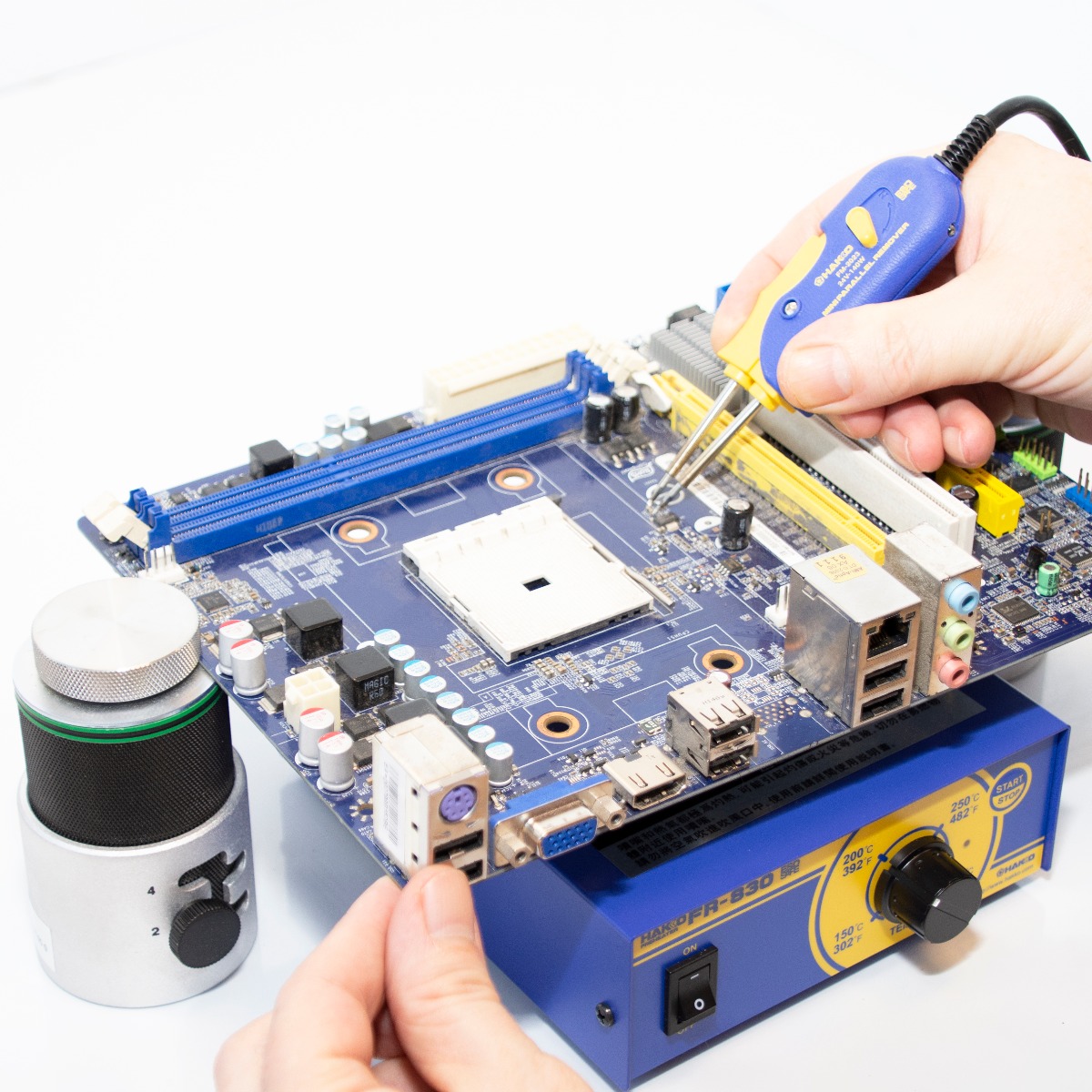

How to use

| |||||||

You may also like…

- Shop by brand, HAKKO, Product catalogue, Rework accessories, PCB Holders / stands, Accessories, FR-830, Spare parts, Replacements for accessories, Underboard heaters, FR-830

C1390C Omnivise PCB Holder

Shop by brand, HAKKO, Product catalogue, Rework accessories, PCB Holders / stands, Accessories, FR-830, Spare parts, Replacements for accessories, Underboard heaters, FR-830

Shop by brand, HAKKO, Product catalogue, Rework accessories, PCB Holders / stands, Accessories, FR-830, Spare parts, Replacements for accessories, Underboard heaters, FR-830C1390C Omnivise PCB Holder

- PCB holder with adjustable height levels

- Holds the PCB steady for rework or repair

- Adjustable PCB opening

- Adjustable Height

- Padded jaws to protect from damage to delicate surfaces

- Best bought as a pair

SKU: HC1390C